Gold-Rush Technology and American Pragmatism

The massive scale and diffusion of placer deposits in the Sierra foothills gave California a distinctive advantage in nineteenth-century America's race for riches. No other region in North America offered such golden opportunities for so many ordinary people, people without specialized knowledge or skills. The California Gold Rush was both first and biggest in sheer numbers of people involved. It was also the

most important, for it accelerated the pace of American urban-industrial development and continental conquest. [14]

American gold seekers carried west a technology based on practical application and experience. Engineering as a profession was still in infancy at mid-nineteenth century; those who called themselves engineers were usually pragmatic, seat-of-the-pants technicians and mechanics with little formal education. They stood in sharp contrast to engineers from Europe, especially continental Europe, which had an engineering legacy grounded in theoretical science and mathematics. [15] Lofty in their traditions and training, some European scientists derided American practical engineering, arguing that the "Yankees" were "blundering along" in gold and silver metallurgy and would continue to do so until they studied at European schools like Freiburg in Germany or the London School of Mines. Some Americans agreed. J. Ross Browne, a Californian and the nation's first commissioner of mining statistics, considered the lack of trained American mining engineers a national disgrace: "Our mines and mills are practically managed by foreign experts; we furnish the labor and mechanical ingenuity, but they furnish the scientific skill." [16] His successor, Rossiter Raymond, took a more balanced view, noting wryly that many Americans puffed the superiority of American methods over the rest of the world. "The truth lies between these extremes," he concluded. Both he and Browne called for a national school of engineering, but Congress responded instead with the land-grant college act, leaving the job of training technicians up to the states. [17]

Whatever the need, it was practical miners in the gold-rush era who responded to technological challenges by adapting existing machines and methods to local conditions. Before 1851 the massive scale of surface placer deposits gave practically anyone a chance to mine without the necessity of elaborate equipment or experience. Only after depleting the high-grade shallow gravels did California mining begin to develop more sophisticated technologies. But even then the change was more innovative than revolutionary. As Browne said in 1868, "with all the genius and enterprise of the American people, no important discovery in the way of machinery for mining was made which had not been long in use in South America, Mexico, or Europe." [18] The Washoe pan process, for instance—the first practical method for reducing Comstock silver ores—was an American hybrid, a modification of milling processes used for centuries in Mexico and Germany. [19] By the late 1860s the hallmarks of American mining technology were ingenuity and innovation, rather than originality and invention. Even former scoffers were impressed. Rossiter Raymond's 1869 Report noted with pride that European metallurgists were now coming to the United States to learn from Americans, rather than the other way around. [20]

Technological innovation in gold-rush California, however, was not distinctively American. The notion that Yankees were more ingenious than people from other lands is an ethnocentric stereotype born out of the excessive nationalism of the

nineteenth century. In truth, adapting common tools and methods to local conditions was standard procedure in frontier communities regardless of ethnic or cultural differences. In Canada, for example, frontier Ontario fashioned new techniques from old "whenever it was practical to do so." [21]

In California, those who were actively engaged in seeking gold used whatever tools and methods were at hand, regardless of origin. To excavate and wash bedrock gravels, the first miners along the American River used ordinary picks and shovels, household butcher knives, tightly woven baskets made by native Americans, and frying pans. By the summer of 1848 Georgians, Hispanic Californians, and perhaps transplanted Europeans with placer experience, had introduced sheet-iron pans and wooden bateas (bowls), wooden rockers (cradles) and riffle boxes, and dry-washing and winnowing techniques with blankets and hides. [ 22] A Georgian "was said to have introduced the sluice box on Laird's Hill about April 1850," but this claim is disputed by evidence that it was in use earlier. [23] The sluice was actually an ancient device, used as early as Roman times, although California miners may have reinvented it without being aware of its antecedents. [24] Like its cousins the long tom and the rocker, it employed the power of gravity to concentrate heavier eroded gold from lighter sands and gravels. When mercury ("quicksilver") was available and cheap enough for low-budget operators, miners added it to sluice boxes to "amalgamate" finer gold particles, flour gold, or "dust" that tended to wash away. Amalgamation was another ancient process brought to Mexico by Spaniards in the sixteenth century and to California by both Mexican and Georgian miners. [25] Mercury-coated riffle bars in the bottoms of sluice boxes "captured" gold if it was bright and clean and "free-milling," or not locked up in sulfide compounds or tellurides. "Clean-up" was a simple matter of scraping up the amalgam and heating it on a shovel in an open fire at first, or later in a retort, until the mercury vaporized, leaving behind the "sponge" of gold, which could then be melted and poured into bars for delivery to the mint.

In the Southern Mines, those south of the Mokelumne River, where the influence of Hispanic immigrant miners was stronger, the Spanish batea —a wooden bowl hollowed out of a single block—was at first widely used in the placer diggings, but it soon gave way to the flat-bottomed iron pan preferred by Americans. [26] More influential was dry-washing, or winnowing, a method used extensively by Mexicans in the Southern Mines, where, prior to the organization of water companies, water was scarce in summer and fall. A French traveler in 1848 watched Sonorans between the American and Cosumnes rivers using this technique to extract six or seven ounces of gold per day from dusty gravels. [27] Experienced Mexican placer and hardrock (quartz) miners made other important contributions to California technology until they were chased out after 1850 by jingoistic Americans using both legal and de facto forms of discrimination. [ 28]

Chinese miners demonstrated considerable ingenuity in adapting and altering

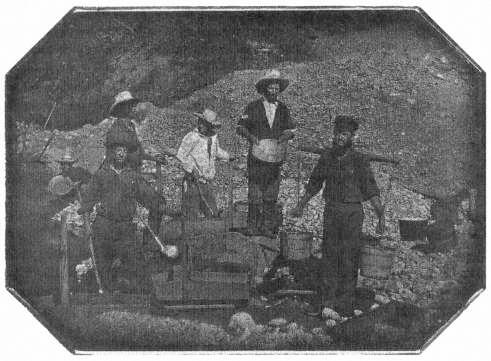

Placer miners pose with the tools of their trade, gold pans and rockers, in what are possibly

dry diggings, to judge by the buckets carried by one of the Argonauts. The rocker, or cradle,

first appeared in California in the summer of 1848, employed at Coloma by miners from Georgia,

who had long experience with its use in their native state. More efficient than the pan, it usually

required the combined labor of two or three men—one to shovel and dig, one to load the hopper

with sand and gravel, one to ladle the water and rock the cradle. Courtesy Bancroft Library .

European and American placer techniques. They were particularly adept with the pan and rocker, continuing to rely on these portable tools long after they were abandoned by others. [29] The image of the Chinese and his rocker became so pervasive in the mining West that some Americans thought the machine was a Chinese invention, even though Isaac Humphreys, a Georgia miner, took credit for introducing it in California. It was used extensively at Mormon's Bar near Coloma and in the ravines and gulches along the American River before the Chinese arrived. [30] But Chinese quickly made the rocker their own. By the 1850s, Chinese models were being manufactured in China and exported back to the United States for sale to new arrivals from the Celestial Kingdom. [31] Historical archaeologists in recent years, after examining numerous Chinese mining sites in the West, have concluded that even as Chinese miners retained cultural identities through an international trade network that supplied them with traditional Chinese commodities, they were re-

ceptive to technological innovation. Thus, as Michael Ostrogorsky puts it, "ethnicity became secondary to technology in determining frontier lifeways, rather than the reverse." [32]

One ancient device distinctively Asian in design, however, saw widespread application and adaptation in the placer camps. This was the Chinese chain pump, a continuous belt of water-lifting pallets, initially foot-powered, that could be used to de-water flooded claims and boggy ground adjacent to a river or stream, or to divert water from a low-lying stream to a nearby sluice or riffle box. Used extensively in river mining, it was widely adapted and quickly altered, growing both in size and capacity, the Asian ancestor of the bucket-line dredge. [33]

Starting with simple, universal designs, practical miners fashioned and re-fashioned mechanisms suitable for specialized needs and adapted to regional conditions. Whenever possible they converted hand- or foot-power to water-power or steam, the most available forms of cheap energy in California before the 1890s. At Mokelumne Hill, for example, William Highly in 1860 built a homemade pump for lifting water thirty feet above a flume, using two water wheels, each twenty feet in diameter, placed so that the same water turned both wheels. [ 34] Other practical engineers erected "flutter wheels," sometimes forty feet in diameter, that lifted water in buckets or barrels attached to paddle wheels rotating in the stream's flow. [35]

By the early 1870s, high-pressure water wheels of the California-built Pelton and Knight designs were beginning to revolutionize the power-generating needs of the industry. In districts where water was abundant, Pelton-type wheels were cheaper than steam engines and much more efficient for powering air compressors, pumps, and line shafts. Some innovators even experimented using these "hurdy-gurdy" wheels to power machine drills underground. [36]