2—

Making Old Tools Work Better:

Pragmatic -Adaptation and Innovation in Gold-Rush Technology

Ronald H. Limbaugh

As any American with a newly purchased computer can attest, rapid technological change is both inevitable and unpredictable in modern, urban-industrial societies. Patterns of rapid change seem inherently modernist and international at first glance, a twentieth-century by-product of economic competition, social upheavals, and the clash of arms around the globe. They also appear to be confined to the most economically advanced nations or regions, those having long passed the frontier or formative stage of development.

This brief study of the Gold Rush provides a broader historical view of technological change. It looks at changing patterns of technology in one region on the fringes of Euro-American industrial civilization, initially isolated but rapidly internationalized and altered in ways neither predictable nor invariably progressive. What it finds are similar forces at work, and similar consequences, whether in postmodernist California, 150 years beyond its Argonaut heritage, or in frontier California during the 1840s and 1850s. The legacy of the Gold Rush lives still in cities and industries that benefited from mining technology, and in the attitudes, lifestyles, and material culture of modern Californians.

While historians traditionally have emphasized the cultural roots of technological change, recent trends in historiography indicate how profoundly the "new" history has been influenced by related disciplines, especially the fields of historical archaeology and geography. Since the 1980s, historians of the American frontier are inclined to view technological change and innovation as a product not only of cultural eclecticism and pragmatic adaptation, but also of the regions material environment. Dianne Newell's study of the Canadian frontier in Ontario, for example, found that innovative technology "was typically cast on a small scale, tailored to local sources of fuel, built from cheap materials available locally—notably wood—and

easy to maintain."[1] Farther west, environmental differences help explain why mining and milling in northern Mexico and the American Southwest relied primarily on semi-arid technology, while northern California's relative abundance of water and timber produced a regionally distinctive technology widely copied but not widely successful outside its most optimal geographic boundaries.

Recognizing the importance of the physical setting as an influence on technological innovation, however, is not to endorse any theory of environmental determinism, a discredited idea among modern geographers as well as historians. Much closer to the mainstream scholarly view is Peter J. Hugill's cautious assertion that "environmental conditions influenced society's range of choices."[2] In California during the mid-nineteenth century, culture, pragmatism, and the regional environment combined to produce complex and dynamic patterns of change in mining technology.

American Mining Technology at Midcentury

The Gold Rush came at an optimal time for American technological development. For the first time in history, the Western world at mid-nineteenth century united science and technology in a revolutionary merger that provided a powerful stimulus for material growth.[3] The next fifty years saw a tremendous change in the mining industry as the industrial revolution spread worldwide, stimulating the demand for minerals, transportation, consumer goods, new sources of power, and capital.

These prospects for rapid technological change were not that apparent at mid-century, however. Before the late 1840s, traditional European mining technology and equipment prevailed.[4] Spain had brought to Mexico in the sixteenth century a technology inherited from the Romans in antiquity and from the Germans in the Middle Ages.[5] The global stock of metals was in short supply, with gold production nearly moribund, silver mining in decline, and only a few base metals available, mainly iron, copper, lead, and tin, which were controlled by Europeans, particularly the British.[6] In the early decades of the nineteenth century, prospectors had located gold in Georgia and the Carolinas, copper in Michigan's Upper Peninsula, and lead and zinc along the Mississippi in Illinois, Wisconsin, and Missouri, but those strikes failed to attract much attention outside their immediate regions, and the technology for mineral extraction was crude even by midcentury European standards.

That was soon to change. Britain prepared the way in the 1830s by loosening its export barriers, making legal the exportation of machinery Americans had long been in the habit of smuggling into the States. By 1841 licenses from the British could be acquired for "nearly everything except spinning and weaving machinery."[7] A few years later the Irish potato famine and the decline of tin mining in Cornwall had profound long-range repercussions on California mining. By midcentury, California was in position to benefit from British policy changes as well as from its domestic "distresses."[8]

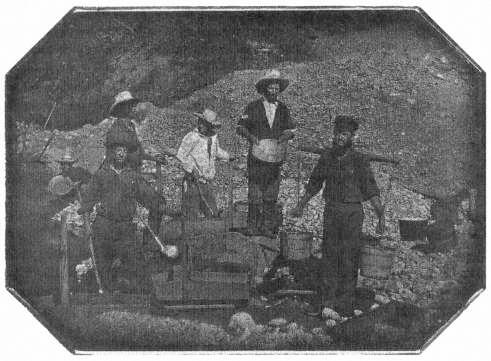

An engraved letter sheet, after a drawing by the famed artist-Argonaut Charles Nahl,

depicts the range of mining techniques practiced in the early years of the gold fever. In

the foreground a miner washes a pan of sand and gravel, intent on catching a glint of

"color," while his companions labor with a cradle, left , and a long tom. Behind them other

miners tunnel into the earth or wash for gold with a line of sluices. California Historical

Society, FN-04130 .

Cultural Stimulus to Technological Innovation

Technology and culture go hand in hand, and California culture at mid-nineteenth century was predominately American, despite the cosmopolitan flavor of the mining camps after the great trek of 1849. Foreign immigration was large during the early statehood years, but historians have tended to exaggerate its size and impact. The foreign-born population never was in the majority. It peaked in 1860 at 39 percent, having climbed from 24 percent in 1850. By the 1870 census the foreign-born element had dropped to 37 percent, and it continued to decline thereafter.[9]

With a two-thirds majority and an ethnocentric chip on their shoulders, Americans at midcentury imposed on California the mainstream values of a highly materialistic, expansionist, overly optimistic society. From the streets of Boston, Philadelphia, and New York, and from the farms and river cities of the trans-Appalachian heartlands, they ventured forth with a robust spirit of individualism and self-worth, an aggressive nationalism, a self-righteous defense of their religious and moral beliefs, and an abiding faith in their own political and social institutions. Unlike the Australian gold rush, which came when Australia was still a colonial province with a pastoral elite in control and with no middle class, the California rush attracted

Americans who were experienced in developing and sustaining local government and social institutions.[10]

Caught up in the heady spirit of Manifest Destiny and Jacksonian egalitarianism, Americans in the late 1840s and early 1850s brought to the Far West an "emotional dynamism" that was both progressive and materialistic. Their material ambitions reflected a common trait found in all Argonauts regardless of race, class, or national origin. H. J. Habakkuk's remark about Europeans applies equally well to other gold seekers: those who left for California had a personal desire to improve by "ensuring, through hard work, that they did in fact better themselves. [ 11]

The federal role in California mining was no less important than the power of democratic idealism. For a half-century prior to the Gold Rush, expansionists and visionaries had postulated a continental empire, a land of small farmers and individual entrepreneurs, aided and abetted by government but left for individual or corporate development without federal intervention or control. This Jacksonian image of democratic capitalism had an important ally in Christian morality and ideology. Historian John F. Kasson found a vital midcentury linkage between religious values and technological progress. When Lyman Beecher, Presbyterian theologian and father of Harriet Beecher Stowe, said Christianity was important "in safeguarding American technology," his message brought a provocative response from the nation's most prominent Unitarian orator, Edward Everett. He replied that "the converse was true. . . . Technology stood as the great benefactor of the public good, and he who impeded the progress of modern inventions threatened all. [12]

Even government could not stand in the way of progress by the thousands of "expectant capitalists" who ventured west in search of fortune. Unlike Canadian or Australian mineral rushes, where government made an effort, not always successfully, to regulate the use of public resources, gold seekers in California had a free hand, helping themselves to land, timber, water, and minerals, with government aiding and abetting the privatization at public expense. Before 1878, for instance, mining interests used thousands of acres of timber lands not legally open to settlement except under homestead and preemption laws. Even those restrictions were ignored by early sawmill owners and miners, who openly cut any timber they wanted on federal lands. [13]

Gold-Rush Technology and American Pragmatism

The massive scale and diffusion of placer deposits in the Sierra foothills gave California a distinctive advantage in nineteenth-century America's race for riches. No other region in North America offered such golden opportunities for so many ordinary people, people without specialized knowledge or skills. The California Gold Rush was both first and biggest in sheer numbers of people involved. It was also the

most important, for it accelerated the pace of American urban-industrial development and continental conquest. [14]

American gold seekers carried west a technology based on practical application and experience. Engineering as a profession was still in infancy at mid-nineteenth century; those who called themselves engineers were usually pragmatic, seat-of-the-pants technicians and mechanics with little formal education. They stood in sharp contrast to engineers from Europe, especially continental Europe, which had an engineering legacy grounded in theoretical science and mathematics. [15] Lofty in their traditions and training, some European scientists derided American practical engineering, arguing that the "Yankees" were "blundering along" in gold and silver metallurgy and would continue to do so until they studied at European schools like Freiburg in Germany or the London School of Mines. Some Americans agreed. J. Ross Browne, a Californian and the nation's first commissioner of mining statistics, considered the lack of trained American mining engineers a national disgrace: "Our mines and mills are practically managed by foreign experts; we furnish the labor and mechanical ingenuity, but they furnish the scientific skill." [16] His successor, Rossiter Raymond, took a more balanced view, noting wryly that many Americans puffed the superiority of American methods over the rest of the world. "The truth lies between these extremes," he concluded. Both he and Browne called for a national school of engineering, but Congress responded instead with the land-grant college act, leaving the job of training technicians up to the states. [17]

Whatever the need, it was practical miners in the gold-rush era who responded to technological challenges by adapting existing machines and methods to local conditions. Before 1851 the massive scale of surface placer deposits gave practically anyone a chance to mine without the necessity of elaborate equipment or experience. Only after depleting the high-grade shallow gravels did California mining begin to develop more sophisticated technologies. But even then the change was more innovative than revolutionary. As Browne said in 1868, "with all the genius and enterprise of the American people, no important discovery in the way of machinery for mining was made which had not been long in use in South America, Mexico, or Europe." [18] The Washoe pan process, for instance—the first practical method for reducing Comstock silver ores—was an American hybrid, a modification of milling processes used for centuries in Mexico and Germany. [19] By the late 1860s the hallmarks of American mining technology were ingenuity and innovation, rather than originality and invention. Even former scoffers were impressed. Rossiter Raymond's 1869 Report noted with pride that European metallurgists were now coming to the United States to learn from Americans, rather than the other way around. [20]

Technological innovation in gold-rush California, however, was not distinctively American. The notion that Yankees were more ingenious than people from other lands is an ethnocentric stereotype born out of the excessive nationalism of the

nineteenth century. In truth, adapting common tools and methods to local conditions was standard procedure in frontier communities regardless of ethnic or cultural differences. In Canada, for example, frontier Ontario fashioned new techniques from old "whenever it was practical to do so." [21]

In California, those who were actively engaged in seeking gold used whatever tools and methods were at hand, regardless of origin. To excavate and wash bedrock gravels, the first miners along the American River used ordinary picks and shovels, household butcher knives, tightly woven baskets made by native Americans, and frying pans. By the summer of 1848 Georgians, Hispanic Californians, and perhaps transplanted Europeans with placer experience, had introduced sheet-iron pans and wooden bateas (bowls), wooden rockers (cradles) and riffle boxes, and dry-washing and winnowing techniques with blankets and hides. [ 22] A Georgian "was said to have introduced the sluice box on Laird's Hill about April 1850," but this claim is disputed by evidence that it was in use earlier. [23] The sluice was actually an ancient device, used as early as Roman times, although California miners may have reinvented it without being aware of its antecedents. [24] Like its cousins the long tom and the rocker, it employed the power of gravity to concentrate heavier eroded gold from lighter sands and gravels. When mercury ("quicksilver") was available and cheap enough for low-budget operators, miners added it to sluice boxes to "amalgamate" finer gold particles, flour gold, or "dust" that tended to wash away. Amalgamation was another ancient process brought to Mexico by Spaniards in the sixteenth century and to California by both Mexican and Georgian miners. [25] Mercury-coated riffle bars in the bottoms of sluice boxes "captured" gold if it was bright and clean and "free-milling," or not locked up in sulfide compounds or tellurides. "Clean-up" was a simple matter of scraping up the amalgam and heating it on a shovel in an open fire at first, or later in a retort, until the mercury vaporized, leaving behind the "sponge" of gold, which could then be melted and poured into bars for delivery to the mint.

In the Southern Mines, those south of the Mokelumne River, where the influence of Hispanic immigrant miners was stronger, the Spanish batea —a wooden bowl hollowed out of a single block—was at first widely used in the placer diggings, but it soon gave way to the flat-bottomed iron pan preferred by Americans. [26] More influential was dry-washing, or winnowing, a method used extensively by Mexicans in the Southern Mines, where, prior to the organization of water companies, water was scarce in summer and fall. A French traveler in 1848 watched Sonorans between the American and Cosumnes rivers using this technique to extract six or seven ounces of gold per day from dusty gravels. [27] Experienced Mexican placer and hardrock (quartz) miners made other important contributions to California technology until they were chased out after 1850 by jingoistic Americans using both legal and de facto forms of discrimination. [ 28]

Chinese miners demonstrated considerable ingenuity in adapting and altering

Placer miners pose with the tools of their trade, gold pans and rockers, in what are possibly

dry diggings, to judge by the buckets carried by one of the Argonauts. The rocker, or cradle,

first appeared in California in the summer of 1848, employed at Coloma by miners from Georgia,

who had long experience with its use in their native state. More efficient than the pan, it usually

required the combined labor of two or three men—one to shovel and dig, one to load the hopper

with sand and gravel, one to ladle the water and rock the cradle. Courtesy Bancroft Library .

European and American placer techniques. They were particularly adept with the pan and rocker, continuing to rely on these portable tools long after they were abandoned by others. [29] The image of the Chinese and his rocker became so pervasive in the mining West that some Americans thought the machine was a Chinese invention, even though Isaac Humphreys, a Georgia miner, took credit for introducing it in California. It was used extensively at Mormon's Bar near Coloma and in the ravines and gulches along the American River before the Chinese arrived. [30] But Chinese quickly made the rocker their own. By the 1850s, Chinese models were being manufactured in China and exported back to the United States for sale to new arrivals from the Celestial Kingdom. [31] Historical archaeologists in recent years, after examining numerous Chinese mining sites in the West, have concluded that even as Chinese miners retained cultural identities through an international trade network that supplied them with traditional Chinese commodities, they were re-

ceptive to technological innovation. Thus, as Michael Ostrogorsky puts it, "ethnicity became secondary to technology in determining frontier lifeways, rather than the reverse." [32]

One ancient device distinctively Asian in design, however, saw widespread application and adaptation in the placer camps. This was the Chinese chain pump, a continuous belt of water-lifting pallets, initially foot-powered, that could be used to de-water flooded claims and boggy ground adjacent to a river or stream, or to divert water from a low-lying stream to a nearby sluice or riffle box. Used extensively in river mining, it was widely adapted and quickly altered, growing both in size and capacity, the Asian ancestor of the bucket-line dredge. [33]

Starting with simple, universal designs, practical miners fashioned and re-fashioned mechanisms suitable for specialized needs and adapted to regional conditions. Whenever possible they converted hand- or foot-power to water-power or steam, the most available forms of cheap energy in California before the 1890s. At Mokelumne Hill, for example, William Highly in 1860 built a homemade pump for lifting water thirty feet above a flume, using two water wheels, each twenty feet in diameter, placed so that the same water turned both wheels. [ 34] Other practical engineers erected "flutter wheels," sometimes forty feet in diameter, that lifted water in buckets or barrels attached to paddle wheels rotating in the stream's flow. [35]

By the early 1870s, high-pressure water wheels of the California-built Pelton and Knight designs were beginning to revolutionize the power-generating needs of the industry. In districts where water was abundant, Pelton-type wheels were cheaper than steam engines and much more efficient for powering air compressors, pumps, and line shafts. Some innovators even experimented using these "hurdy-gurdy" wheels to power machine drills underground. [36]

The Legacy of California's Gold-Rush Technology

Granted the accelerated pace of development in the West following the international rush of 1849, what were the long-range consequences for California mining technology? John Hittell, California's first regional historian, admitted that western miners were eclectic rather than original. Even so, he continued, their lack of originality "does not deprive the miners of the Sacramento basin of their right to high credit; for although the general principles might have been elsewhere applied at an earlier time, it was here that the inventions were brought to their highest state of efficiency, that they were universally adopted, and that they were adapted to the peculiar circumstances of every locality." [37]

Writing in 1861 about the state's brief mining history, Hittell had the advantage of both his personal observation and a ten-year perspective. By that date California had moved beyond the egalitarian era. Mining was no longer dominated by indi-

vidual entrepreneurs or small partnerships in search of high-grade shallow placers. By the late 1850s a new era of industrial mining had dawned, an era characterized by corporate organization and consolidation, substantial capital investment, increased professionalization of management and engineering, hired miners working for wages instead of partners working for profits, and new technologies designed to mine lower-grade massive deposits.

Generally, these industrial conditions applied only to the major mines, whether placer or hardrock. On a different scale entirely were the smaller producers, the true heirs of the Gold Rush. Most mines were still in the hands of small-time operators or companies, the "room and pop" units in the industry. Working with less capital investment, fewer men, smaller properties, and often with antiquated methods and equipment, their numbers were large but the volume of their production modest in comparison to the major producers. Technology made slow progress in these smaller mines for a variety of reasons, some of which had to do with the high cost of change, but mostly because the focus was on high-grade ore extraction, rather than operations that required modernized mass-mining techniques. Dianne Newell's analysis of conditions in frontier Ontario might equally apply to frontier California: in both places high-grade ores, usually close to the surface, were profitable to work without employing expensive new equipment or new technologies. [38] Even after the mines deepened and lower-grade deposits opened, some operators remained in business as long as they could, hoping for another bonanza and financing operations with production revenue when possible, or with "Irish dividends"—stock assessments—when not. Often the mine ended in failure and foreclosure, only to start up again with a new source of ore and a new cycle of intermittent production and decline. Though such operations dotted California throughout its mining history, they generally remained economically insignificant and technologically limited.

California miners may not have been the heroic architects of western technology that John Hittell described in 1861, yet his praise is not wholly unwarranted. By that time, two components of the industry, hydraulic mining and stamp milling, had been indelibly marked with regional distinction.

Hydraulic Mining: A California Original

Because of "our peculiar circumstances and conditions," wrote Rossiter Raymond in 1869, the United States has "developed some distinctively American processes." One was hydraulic mining, "native and peculiar to this country," a technology distinctly Californian in design and application. [39] Historians have quibbled about whether it was really "new" or merely another example of adaptive innovation, [40] and have even disputed the place of origin and the originators. [41] The details of its genesis should not obscure the larger significance of its contribution to mining. It was truly a

"breakthrough technology," [42] a revolutionary process using the destructive power of high-pressure water to exploit thick, deeply buried placer deposits at the lowest possible cost. It proved the effectiveness and profitability of working lower-grade ores with mass-mining techniques.

The need for new placer technology became apparent as early as 1850. Cornish miners in Nevada County, following gravel leads that indicated the presence of deep gravels laid down by ancient river channels, sank short vertical shafts to bedrock, then drifted along the channel to locate the "pay streak." Pocket mining, or "coyoting," a common practice among prospectors and small operators in the early 1850s, expanded into drift mining or "tunneling," designed to exploit the richer gravels deposited in a complex series of Tertiary streambeds, buried fifty to two hundred feet or more below the surface. [43]

Drift mining was both dangerous and expensive, requiring more experience and skill than surface placering as well as a greater outlay of capital for underground development and timbering. It was also inefficient, requiring miners to remove tons of barren rock and gravel before reaching pay dirt. [44] In hilly localities, where there was abundant water and adequate drainage, some companies resorted to "ground sluicing." This was an inexpensive way to strip off shallow "overburden," or barren material above bedrock, simply by washing it away with a large volume of swift-running water and allowing the cracks and crevices in the rocky underlay to serve as natural riffle bars for capturing loose gold. Most of the finer particles washed away with the barren sands, but enough gold was caught by this means to make ground sluicing a popular and cheap method of moving massive amounts of material. Philip R. May characterized it as the "essential preliminary technique" to hydraulic mining, since it demonstrated both the earth-moving potential and the economic feasibility of mass-mining by hydraulic action. [45] All that remained was to devise means and methods to increase the velocity and cutting-power, and control the direction of the stream flow.

Hydraulic technology advanced incrementally and differentially, with local inventors working independently to design and patent components. Edward E. Matteson is credited with devising the first successful nozzle. A Rhode Island native and Forty-niner, he added a three-quarter-inch nozzle made of sheet brass to a rawhide hose attached to a barrel set on a stump thirty feet above him, using it for the first time in March 1853 to undercut a steep, high bank that he had been ground sluicing with a stream of water. [46]

Matteson's homemade device was a great success, but as Randall Rohe points out, hydraulic technology could not keep up with demand. Canvas replaced rawhide by 1853, but it was expensive, prone to rot, and unable to withstand the increased pressures demanded by hydraulic operators. Iron pipe eventually replaced not only the hydraulic hose but most of the wooden flumes that had mushroomed in the

A half-dozen miners combine their labor in ground sluicing, turning a stream of water to wash

over a bank of earth and assist them in cutting down to the pay dirt of the gold-laden gravels

resting on the bedrock below. Used extensively beginning in 1851, the technique was a

precursor to hydraulic mining. Courtesy Huntington Library, San Marino, Calif .

1850s, as hydraulic water companies devised elaborate and expensive delivery systems to supply the mines. Nozzles were fitted to iron "monitors," which also expanded in size, capacity, and maneuverability. Gooseneck swivels and knuckle joints provided both horizontal and vertical movement of these powerful water cannon, rock-filled boxes counterbalanced the water velocity and volume, and solid tripods and pivots added stability and support. By the 1870s, hydraulic monitors, or "giants," came in a variety of shapes and sizes, some weighing a ton or more. Most were designed and built by local technicians in machine shops and foundries both in San Francisco and in regional mining and supply towns. [47]

Aside from the systems for water delivery and discharge for washing down the banks, hydraulicking was a relatively simple and ancient technology that relied on traditional gravity methods. Except for the largest boulders, all the material washed down by hydraulic operators passed through long strings of sluice boxes on its way downstream, leaving huge pits behind and tons of debris clogging the streams and rivers below. Like their shallow-placer-mining colleagues, hydraulic miners relied on amalgamation for recovery of values. Clean up and retorting recovered most of the mercury, but invariably a small percentage escaped, leaving a troubling legacy of pollution for later generations. More immediate was the devastation imposed on

A slender stream of water plays against a high bank at Michigan Bluff, Placer County, in a

daguerreotype made in the spring of 1854, one of the earliest known photographs of hydraulic

mining. It was from such simple and innocent beginnings that the giant cast-iron monitors of

the 1870s evolved. These water cannons, with bores of six to ten inches, could throw a powerful

jet of water several hundred feet and tear away whole hillsides in an afternoon. Courtesy Wells

Fargo Bank .

farmers and merchants and families in the Central Valley by the periodic floods that washed millions of tons of hydraulic debris downstream, filling in riverbeds and smothering farms and towns. After a decade of lawsuits, the federal courts in 1884 dealt a near-fatal blow to this branch of the industry in California by requiring that miners impound all hydraulic tailings.

For nearly three decades, hydraulic mining dominated northern California as had no other form of mineral extraction. But as historian Robert Kelley put it, in the confrontation wrought by two clashing technologies, mining and agriculture, Californians chose "grain" over "gold. [48] Yet hydraulicking was the first effective technique for mass-mining of lower-grade deposits, and as such it set important precedents for the industry. It also stimulated the development of significant ancillary industries in California, particularly systems for impounding and diverting water,

both for irrigation and urban use. The legacy of hydraulic mining lives on today in California, a state still embodying, as some have contended, the characteristics of a "hydraulic society. [49]

Developments in California Hardrock Technology

A later but still vital technological component of the California Gold Rush was hardrock, or lode, mining. It began in 1849, rose quickly between 1850 and 1852, then collapsed, rising again later in the decade and eventually dominating the industry. But hardrock mining's path to commercial viability was tortuous, filled with geologic, technological, and economic pitfalls that took many years to overcome.

As early as the spring of 1849, prospectors near Mariposa found pockets of highgrade gold ore among the quartz outcrops along a mineralized fault zone eventually traced for nearly two hundred miles. Miners called it the "Mother Lode," and popular literature today has often confused it with the more productive foothill deposits farther north in Nevada County, where California hardrock mining had its longest and most lucrative stand. But the initial excitement, overlaid with geologic ignorance and economic impetuosity, focused on the Southern Mines, where the outcrops were most extensive. Enthusiastic mine promoters imported European machinery at great expense, overbuilding the surface plant before understanding the size and nature of the orebody—a management mistake all too common in early American hardrock mining. After two or three years of effort, underwritten primarily by naive British investors relying on dubious field reports prepared by inexperienced and self-serving operators, the bubble burst. The mines shut down, the surface plants were abandoned, and investment capital dried up, leaving a sour taste for hardrock mining that took years to overcome. [50] A contemporary British observer, writing from Mariposita in the fall of 1852, recorded the frustration by noting that the "character of the country has yet to be ascertained, and it will not be found out by the guesser or mere prospector, but by the man of practice and experience. At present all is guess, and hope, and chance." [51] Rossiter Raymond later attributed the failure to "errors of judgment" rather than to "gross mismanagement," pointing out that Old World mining methods were inapplicable in California because of differences in ore character, labor costs, scarcity of materials, and climate. [52]

To remedy the situation, as Rodman Paul, the late dean of modern California mining historians, has written, a few practical miners, burned by the initial failures, inaugurated the "real beginning" of hardrock mining in California in the early 1850s, when they "set out to teach themselves in the fields of geology, mineralogy, engineering, and mechanics. [53] Building practical experience meant adapting available technologies to local conditions, the same pragmatic approach already seen in the gold-rush placer camps. California miners had much to learn. Their collective ex-

perience with hardrock mining was minuscule in comparison to immigrants from older hardrock districts, both in the United States and abroad. But early quartz mining was relatively simple because only the shallow deposits were worked. Before the 1860s California mines rarely reached levels below three hundred feet, the maximum depth of groundwater. Above that level, gold deposits containing sulfides, or "sulphurets," were subject to the natural processes of oxidation, leaching, and erosion, leaving a zone of "enrichment," higher in grade and easier to mine and mill than the deeper, unoxidized sulfide deposits. Thus, smart early mine operators kept to the shallow, weathered deposits and used simple methods. From more experienced underground miners from England, Germany, Mexico, and the lead and copper mines east of the Mississippi, they learned the basic techniques for opening a mine by vertical shaft or horizontal adit, advancing the heading by drilling and blasting, drifting and crosscutting to locate the most promising leads, draining and ventilating, timbering, and hauling and hoisting ore and waste. [54]

As the mines deepened, more complex technology was needed. Except for the occasional use of donkeys, mules, or horses to pull ore cars, before the 1860s most of the underground work was hand-powered and labor-intensive. Two-man "double-jack" drilling crews were required to set an effective charge with black powder, since drill holes had to be large in diameter. Dynamite needed smaller holes and fewer workers to handle but did not come into practical use until the late 1860s and early 1870s, and even then its use varied from district to district. In Grass Valley mines, where Cornish crews predominated, for instance, black powder and double-jacking remained the prevailing technology until 1869, when managers tried to introduce dynamite. The effort set off a nine-week strike ending in a compromise that kept out dynamite for another three years but opened the mines to single-jacking. Other districts lacking strong Cornish labor representation made a smoother transition to newer technology. [55]

Machine drills eventually replaced hand-drilling, but the change was slow and uncertain. The availability of innovations did not mean they were readily or widely adopted. Air-powered piston drills were not practical for underground work until the 1870s, and the rock dust they kicked up made them dangerous, especially in quartz mines high in silica. Furthermore, the early machines were awkward and expensive to install, requiring a new surface plant, at least two operators, and more space underground than many mines had available. Some historians have argued that labor resistance retarded the introduction of machine drills, although that view has been challenged by more recent scholarship, which has demonstrated that in some mines, at least, the issue was not health or jobs but basic economics. To financially pinched mine managers, the question often was not whether a new machine would work but whether it would help reduce operating costs. Thus machine drills were not widely used in the West until they were smaller, cheaper, more efficient, more durable, and

safer. The real era of machine drilling did not begin until after water-cooled Leyner percussion drills were introduced in the late 1890s. [56]

Technological innovation also depended to some extent on the size and ethnicity of the work force. As John Rowe has observed, Old World technology reflected Old World attitudes and labor practices. In Cornwall, for example, with more workers than jobs available, mining machinery was used primarily to do work that animals and men could not perform; in America, with fewer workers and therefore higher labor costs, machines were designed to replace manual labor. The quality and durability of Cornish machinery also reflected the solid legacy of the Cornish mining heritage and the pride of its craftsmen. In contrast, American machinery was cheaper, less well built, and more easily replaced—a reflection of the newness and speculative nature of American mining—with owners and investors "all the more ready to scrap efficient but slow machines for novelties which promised vaster and quicker returns." [57]

In the mines of the northern Sierra, where the Cornish influence was strongest, Old World technology was reflected in both mining and milling methods. "Cousin Jacks" dominated the drilling crews, and Cornish foremen supervised underground operations. The first Cornish pump in California was installed at the Gold Hill mine in 1855, and the first ore-crushing stamp mills in the district were of Cornish design, although they soon gave way to the improved California mills. [58] Cornish methods also prevailed in the milling cycle. Finely ground mill pulp was discharged into long wooden troughs lined with coarse wool blankets especially made for the purpose. Every fifteen minutes the blankets were carefully removed and washed in amalgamation tanks to recover minute particles of metallic gold. The blanket-washing process, a technology used in Cornwall for centuries, was one of the distinguishing features of what became known as the "Grass Valley System. [59]

The Cornish presence was welcomed by mine and mill managers, many of whom were themselves Cornish, commissioned by English investors counting on their countrymen to protect their mutual interests. [60] Underground and in the surface plants, Cornish mining and milling skill was highly regarded, no less so by their own countrymen. In 1852 W. E. Gill, a Cornish miner from Truro, described his California experiences to a hometown newspaper: "Here some ability must be displayed in separating the gold without a loss, and here John [Bull] respectfully takes leave of Jonathan [Yank]. The latter is evidently a better huxter than a mining engineer. [61] Another Cousin Jack in Michigan, commenting on Cornish resistance to the introduction of dynamite, remarked that "Cornishmen are good miners, and good mine managers—they ought to be—but they are just as apt as others to conclude that what they do not know is not worth knowing." [62]

Along the Southern Mines of the Mother Lode, as in the placer districts, the technology reflected a strong Hispanic heritage. Mexicans were in great demand at

first. They brought with them a four-hundred-year hardrock legacy, though their mining methods were less popular than their milling technology. [63] As Otis Young has observed, with some hyperbole, the Hispanic legacy profoundly influenced American milling. "Until the late 1880's," he wrote, "the western mining frontier depended so heavily upon Spanish milling methods that it is almost correct to say that millmen used little else but Spanish techniques hooked up to steam engines." [64] "Almost" is the great qualifier in this statement, especially as it applies to northern California, since that region produced ores distinctly different from those in the Southwest and Mexico, requiring different milling methods.

The most important Spanish technique to California millmen was the arrastra , a shallow, rock-lined circular pit where hand-sorted and broken ore could be ground and amalgamated by drag-stones powered by horse, mule, or waterwheel when sufficient water was available. Simple to construct and operate, using local materials widely available, it was the only successful milling tool for quartz miners in the early days. The Chilean mill, which crushed ore under millstones rolling over a stone patio or iron pan, was also used to a limited extent, and the principle was later employed in rotary grinders such as the Huntington mill, a widely used, medium-sized secondary crusher of California origin. [65] But traditional "Chili mills" and "rasters" were too small and slow for American miners, who needed a higher volume of production to meet lode mining's heavy capital expenditures and labor costs. [66]Arrastras continued to be used, mostly for reprocessing tailings, right into the twentieth century, but for bulk secondary crushing Americans turned to the stamp mill.

The California Stamp Mill

Pulverizing ore by mortar and pestle was an ancient technique. Prospectors used small mortars to test quartz outcrops during the Gold Rush, but the same principle had been used long before to develop a mechanical crusher common in European mills. Agricola claimed it had been invented in the late fifteenth or early sixteenth centuries, and found it in use in the mining districts of Germany and Switzerland. [67] Otis Young, emphasizing its southwestern connections, claimed the Spanish maza , or water-powered mill, a device using a single wooden pestle, or "stamp," and a square stone mortar, was "evidently a progenitor of the 'California' gravity stamp mill." [68] Rodman Paul believed stamp-mill technology arrived in the Far West by way of the American South, where it was in place in Georgia, Carolina, and Tennessee by the 1830s and 1840s. [69] Others claim the honor for Cornwall, noting that Cornish miners brought hardrock milling methods to California at least before 1855. [70]

Whatever their origin, imported mills were inadequate to meet California needs. German and Mexican mills used wood for pestle stems and mortar boxes, both subject to warping or leaking when wet and too flimsy for heavy use. Cornish and

The interior of a quartz mill at Grass Valley, Nevada County, the leading center of hard-rock

mining, as illustrated in the October 1857 issue Hutchings' California Magazine . To the rear

stand two four-stamp batteries, or mills. The cast-iron "stampers," or pestles, weighing from

six hundred to a thousand pounds, were raised by the revolving horizontal driveshaft and

then fell with tremendous force to crush fist-sized pieces of ore to powder. California

Historical Society, FN-30967 .

Spanish mills had iron stems, split at the lower end and welded onto a cast iron shoe. Stamp heads in these older models were square and wore unevenly as the shoe dropped constantly on the same spot. The mortars were open at the bottom and mounted on stone plates or bedrock. Ore was broken and fed by hand to each stamp, which crushed dry and unevenly with an ear-shattering noise, accompanied by billowing clouds of silica dust. [71]

American millmen, working with these erratic imports, engineered pragmatic alterations whenever necessary, borrowing ideas and designs freely. The result by the 1860s was a regional hybrid, the "California improved stamp mill." The standard unit consisted of a mechanical jaw crusher for breaking rock, an automatic feeder, a five-stamp battery with fine-tooled, interchangeable parts, a heavy iron mortar, and an apron over which the pulp flowed on its way through the milling circuit. Most California mills used primary crushers manufactured in San Francisco from designs by Eli Whitney Blake, an authentic Connecticut Yankee who invented the machine in the 1850s for road construction work. [72] Gravel-sized ore mixed with water and fed into the mortar was ground between cast-iron shoes fitted onto the stamp heads and cast-iron dies attached to the mortar floor. Shoes and dies were easily removed for repair or replacement. A wooden bull wheel powered by water or steam in the early days, and electricity after 1890, turned a camshaft that lifted and rotated tappets connected to each stamp in a sequence designed to spread the wear and the pulp evenly. The mortar, a cast-iron box weighing several tons, came in various shapes and sizes to meet individual milling requirements. [73]

California gold mills, unlike silver mills in Colorado and the Southwest before the 1890s, usually wet-stamped, adding mercury along with water and reagents to the mortar box during the grinding process to improve recovery. [74] Wet-stamping in battery eliminated the dust problem and lowered the noise to a muted thunder, still too loud for millmen to talk normally but less harmful to the psyche, if not to the hearing. More important to millmen, wet-stamping helped to equalize the pulp, to keep it flowing in wave-like pulses through the mortar screens, and to clean the gold for better amalgamation. In mills that preferred dry-stamping, the improved California design closed the battery "as tightly as possible" and added a blower to move the dust into settling chambers, sometimes with the aid of steam. [75]

By the 1860s the California mill had become the standard design in the mining West, regardless of the type of ore, the size of the orebody, or the financial condition of the mine or mill. Single, five-stamp batteries found their way to remote mining camps throughout the West as well as overseas. In the larger mining districts west of the Rockies, twenty-, forty-, and sixty-stamp mills were not uncommon. Most of this complex equipment, along with hundreds of other types of mining and milling machinery and parts, was produced in San Francisco. More than forty foundries, machine shops, and iron works operated in the city by the mid-1860s—contributing to

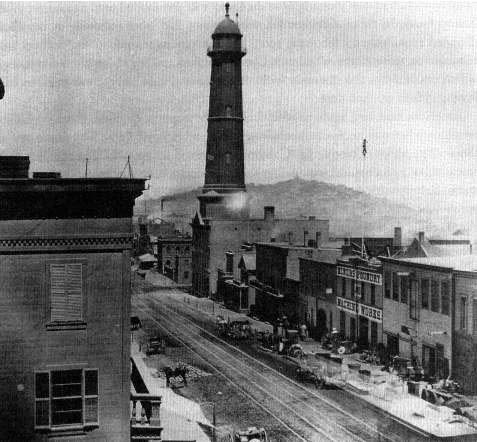

A horse-drawn wagon moves slowly past the Miners' Foundry and Machine Works on

First Street, just north of Folsom, in San Francisco, about 1865. The iron working industry

had its origins in the American West less than a mile from here, when in the summer of 1849

James Donahue rigged up a simple charcoal forge for a smithy. With the rise of hydraulic

and hardrock mining, the demand for castings soared, and the foundries and machine shops

of San Francisco quickly earned a national reputation for fabricating superior mining

machinery. Courtesy Society of California Pioneers .

San Francisco's status as the industrial capital of the West during the Gold Rush and for nearly a half-century beyond. [76]

East of the Rockies, ironworks in Chicago and other cities also began building California-type mills, usually modified to meet regional conditions. Colorado's complex silver ores, for example, much higher in sulfides than simpler California gold ores, needed deeper mortars, a longer and slower drop, lighter stamps, and a finer grind for efficient milling. [ 77]

Before the development of cyanidation and flotation, fine grinding was usually a

curse for the millman who depended on gravity separation to treat gold and silver ores. The finer the grind the more likely the prospect of "sliming" the ore and "touring" the mercury if battery amalgamation was used. "Slimes" were particles of mixed ore and "gangue," or nonmetallic waste, crushed and ground so fine that gravity had little effect. Most slimes could not be captured by ordinary gravity-separation processes and were thus lost in the tailings. California stamp mills were prone to sliming if not carefully monitored. But they lasted well into the twentieth century, economically and efficiently working away even in the major mills long after more effective ball and rod mills were available. As one practical engineer, a member of the Technical Society of the Pacific Coast, commented in 1900, "some one will probably invent a better machine than the California quartz mill for crushing rock and catching gold. It has its faults, and yet its much-condemned sliming tendency is too often the fault of the millman. It is simple, relentless and conscientious, with fewer faults than cling to many of its operators. [78]

Gold-Rush Technology and Emerging Professionalization

Gold-rush technology was characterized by a frontier phalanx of enterprising amateurs altering or upgrading traditional techniques to meet local conditions. These were practical men—miners, millmen, blacksmiths, self-taught engineers, and other artisans—working independently at the job site or nearby on innovations designed for specific tasks. They were responsible for bringing hydraulic mining, drift mining, and stamp milling to the peak of perfection, and were behind many of the other machines and methods associated with the mining industry in nineteenth-century California.

Alongside them gradually emerged another technological prototype, the professional engineer, but it was a long struggle. Gold-rush miners and their followers generally believed that experience was the only sure path to pay dirt. Educated engineers or geologists were thought too theoretical, too unfocused and impractical, to work in the field either as prospectors or managers. Most professional engineers before 1870 were foreigners, trained in European schools—another mark against them in the minds of Americans still brimming with the fervent nationalism of the Jacksonian era. [79]

As the mining industry stabilized and expanded by the 1860s and 1870s, and as new investment capital came into California after the Civil War, new technology and science also entered. Deeper mining required more complex geological knowledge and more sophisticated machinery and methods. Investors wanted better information, the advice of experts, before risking their money. As the industry changed, so did the older ways of thinking. Mine managers and millmen, once resistant to sci-

ence, now became more receptive, especially if science had practical application. The result was an increasing opportunity for professionals in the mining industry. [80]

One manifestation of this changing view was the clamor for a statewide geological survey. In the early 1850s, the legislature had appointed a state geologist, John B. Trask, but he was an "enthusiastic amateur," unequal to the task. In the waning years of the Gold Rush, renewed calls for a systematic state survey led to the 1858 appointment of Josiah D. Whitney as director. He was a professional geologist trained at Yale and in Europe, with a distinguished record. Expecting a thorough analysis of ore deposition in California, however, the mining interests were disappointed in the results. Over a thirteen-year period, Whitney and his professional staff produced and published a compendium of California natural history rather than a catalog of mineral resources. The volumes were little immediate help to the regional mining industry, but, as Rodman Paul has noted, the California Survey was the training ground for many geologists who went on to do important work at both federal and state agencies. [81]

At the federal level, some geologists first found jobs in a national agency organized at the urging of U.S. Senator Cornelius Cole of California and the mining interests that backed him. They proposed a national mining bureau to gather data on specific mining regions and operations. The result was congressional legislation in 1866 that established the office of U.S. Commissioner of Mining Statistics under the Treasury Department. The ten annual reports issued during the agency's brief existence by commissioner J. Ross Browne, a Californian, and his successor Rossiter Raymond were filled with technical information gathered by an excellent field staff and are still valuable today as an important source of historical data on mining west of the Rockies. [82] Raymond and Browne also contributed occasionally to the Mining and Scientific Press , a San Francisco serial that for sixty years reported comprehensive technical and economic news. Historian H. H. Bancroft called it "the leading journal on all matters connected with mining." [83]

In the 1870s the Treasury Department's Office of Mining Statistics was superseded by the U.S. Geological Survey, the agency ultimately responsible for gathering and disseminating information on American science and technology. Beginning in 1879 with the production of topographical maps, then moving to the classification of public domain lands, within a decade the Geological Survey was providing many services directly benefiting the mining industry, including "topography, geology, paleontology, chemistry, illustrations, mineral resources, library, irrigation, and engraving geologic maps. [84]

More directly beneficial to California mining was the State Bureau of Mines, established in 1880 by the legislature at the behest of mining interests. Headed by a state mineralogist appointed by the governor, the bureau was empowered to collect and preserve mineral specimens and detailed information on mining and milling

methods, cultivate mining and metallurgical education, make on-site inspections, and prepare detailed reports on mining operations in each district throughout the state. With dedicated professional staffing, the bureau soon proved its worth by inaugurating a series of informative reports, bulletins, and technical leaflets that continue to the present day. [85]

Another result of the interest in professionalization was the first state efforts to provide technical education. Taking advantage of the federal Morrill Act (1862), giving public lands to the states for educational purposes, the California legislature in 1865 first proposed an "Agricultural and Mechanical Arts College." Under pressure from mining interests the lawmakers soon revised the title to "Agricultural, Mining, and Mechanical Arts College," and added a sentence emphasizing "the application of mechanical arts to practical agriculture in the field and mining." Opening in 1868, the new college, renamed the University of California, took years to graduate its first geologists and engineers. In the meantime eastern and European schools supplied the state with trained personnel. [86]

The presence of immigrant and later home-educated professionals increased the potential for rapid technological advances in California mining and milling, but the rate of change was differential, erratic, and unsystematic. Each sector of the industry independently moved forward, or sometimes backward, depending on local circumstances and personnel. In gold milling, for example, the Grass Valley System was widely adopted in California, but by the 1870s millmen could choose among a variety of techniques, each claiming advantages in cost and efficiency. The choice depended essentially on the type and grade of ore to be processed, matters that required professional training in mineralogy and metallurgy. G. F. Deetken, the man credited with perfecting the Grass Valley System, developed an elaborate procedure that began with fine-crushing and amalgamating in the stamp battery, then discharging the pulp onto blankets to catch the "fines," cycling the slimes and sands through several amalgamating tanks and tables for additional concentration to separate gold from gangue, and finally subjecting the concentrates to heating and chlorinating. But his system was designed for ores relatively low in sulfides. Ores with heavier sulfide content required much different treatment. In the 1880s, M. P. Boss of San Francisco patented a continuous milling process for both gold and silver ores. Touted as less expensive because it saved water and required fewer men to operate, it was also designed to improve the recovery of slimes and floured mercury. The key to this technique was coarse grinding in battery with the "least amount of water requisite to carry the pulp through the screens." Dispensing with blanket troughs and washing tanks, the Boss process discharged pulp into a series of grinding pans with automated mercury feeders, then settlers, and finally through a concentrating circuit. At the California mill in Virginia City, Nevada, completely revamped after the "Big Bonanza" days, the mill tailings were discharged into a series of tailings sluices "ex-

tending down the canyon" toward Dayton. [87] Cyanidation eventually replaced both these systems, but it came slowly to California, not making real headway until after 1900, a decade after it was introduced. By that time almost all California mines were deeper, working in lower-grade ore often higher in sulfides, which were ineffectually treated using only gravity-separation technology.

Conclusion

By the 1870s, California mining still retained vestiges of the gold-rush era but had reached the status of a modern industry. As Rodman Paul has written, it began as an adventure, changed into a business run by practical miners, and finally evolved into an industry in which the "dominant figure" was not the "honest miner" of the foothills but the "financier" and the "highly paid consultant or superintendent who made of mining a science and a profession. [88] This transition to modern mining came not through sweeping technological changes like a rising tide, but by piecemeal, step-by-step movement, mostly forward but often erratic and sometimes lateral or even backward. California mine managers occasionally had a conservative streak, resisting technology that cost money even if it improved efficiency or mine safety. William H. Storms, a California state mining inspector, deplored such parsimony. He publicly condemned the "antiquated" and "objectionable" methods employed by such men as Alvinza Hayward, who opened huge stopes where ore was removed without adequate timbering in order to return quick profits despite the danger. [89]

California mining had distinctive features that marked it as a regional variant if not a separate species. Though the Gold Rush lasted only a few years, it built a foundation for technological progress and urban-industrial development that continues today. The Golden State's timber and water abundance gave it advantages over drier districts and stimulated advances in peripheral technology such as dam and bridge design, dredging and excavating, and hydroelectric generation. Its massive gold deposits made it different from mining regions in the western interior, which had a different geology and a later development. Nowhere else was there such great opportunity for small-scale entrepreneurial mining as in California, which took longer to pass through the pioneer stage than other mineralized regions of the world. Industrial mining eventually arrived, bringing with it rapid technological advances based on adaptive design and pragmatic innovation, and reducing most of the work force to hired hands guided by professional managers. Yet small-scale entrepreneurial mining lingered on into the twentieth century, providing a psychological link to the Gold Rush and a cultural continuity that ties the past to the present. Today's recreational miners, whether with gold pans or suction dredges, still seek instant riches in the chilly waters of foothill streams. But there is also another form of

wealth-seeking in the cities and industrial zones of coastal California, where much of the wealth generated by gold mining eventually came to rest. The legacy of the Gold Rush lives on in the quest for riches in the form of good jobs, good living, personal fulfillment—the same things California Argonauts sought 150 years ago.