Preferred Citation: Cheit, Ross E. Setting Safety Standards: Regulation in the Public and Private Sectors. Berkeley: University of California Press, c1990 1990. http://ark.cdlib.org/ark:/13030/ft8f59p27j/

| Setting Safety StandardsRegulation in the Public and Private SectorsRoss E. CheitUNIVERSITY OF CALIFORNIA PRESSBerkeley · Los Angeles · Oxford© 1990 The Regents of the University of California |

To Budd and June

Preferred Citation: Cheit, Ross E. Setting Safety Standards: Regulation in the Public and Private Sectors. Berkeley: University of California Press, c1990 1990. http://ark.cdlib.org/ark:/13030/ft8f59p27j/

To Budd and June

ABBREVIATIONS

|

ACKNOWLEDGMENTS

This project would not have been possible without the cooperation of countless individuals in the public and private sectors. All of those listed in the appendix provided valuable information and were generous with their time. Hank Collins of Underwriters Labs and Don Mackay of the National Bureau of Standards were extraordinarily cooperative and deserve special thanks.

Friends and colleagues at the Graduate School of Public Policy at the University of California, Berkeley, provided assistance and encouragement of all sorts. I am grateful to Allan Sindler for arranging financial support from the Sloan Foundation, and to my fellow doctoral students for reading the roughest of drafts and providing encouraging criticisms. Glenn Shor and Fritzie Reisner were unusually helpful in both regards. I am also indebted to Martin Trow and Martin Shapiro for their service on my doctoral committee.

John Braithwaite and David Hemenway contributed thoughtful comments on early portions of this work, and Phil Harter was remarkably helpful at a surprising number of stages. I thank John Mendeloff for providing prompt, thorough, and fruitful comments about the entire manuscript in the style of our mutual dissertation advisor, Gene Bardach.

Many colleagues at Brown learned more than they ever wanted to know about grain elevators and woodstoves. Roger Cobb, Jim Morone, Mike Rich, Darrell West, and Alan Zuckerman provided useful sugges-

tions for improving the manuscript. I am particularly grateful to Tom Anton, director of the Taubman Center for Public Policy and American institutions at Brown, for his advice, encouragement, and support. Jason Grumet provided extraordinary assistance in the final stage of this project.

I am forever thankful to my parents for their generous support and genuine interest, and to Kathy Odean for just about everything else that helped make this book a reality.

Most of all, I want to thank Gene Bardach for providing the inspiration for this study, for carefully and critically reading the manuscript several times, and for lending the ideal combination of guidance and encouragement along the way.

PART ONE

INTRODUCTION

One

Protective Regulation and the Impasse Between the Public and Private Sectors

The rise and fall of government regulation challenges both sides in the debate over the proper role of government and business in protecting people against various risks. Leaving business to its own devices is suspect for reasons suggested by horror stories such as the exploding Ford Pinto. The "failures" of the free market are well recognized. Consumers frequently lack information. Businesses often lack the incentive to internalize "external costs" such as pollution. The costs of organizing collective interests can be prohibitive; and without the watchful eye of regulatory inspectors, the unscrupulous lack a powerful reason for self-restraint. But, as the revolt against regulation reveals, government regulation has its own serious shortcomings. As Charles Wolf points out, the "failures" of nonmarket arrangements parallel those of the free market.[1] Many regulatory agencies are plagued by adversariness and delay. Regulations are often slow in coming but quick to court. These regulations can be inflexible and unreasonable. As a result, the political debate over protective regulation has reached an impasse. Proponents of government regulation appeal to well-founded fears of laissez-faire arrangements, while supporters of the private sector appeal to similarly substantiated concerns about regulatory bureaucracy.

In the heyday of protective government regulation, the late 1960s and early 1970s, nearly two dozen new federal agencies were created, including the Occupational Safety and Health Administration (OSHA), the Consumer Product Safety Commission (CPSC), and the Environ-

mental Protection Agency (EPA). These agencies were born of an "entrepreneurial politics" that, according to James Q. Wilson, capitalized on general antibusiness sentiment and specific "horror stories" from the private sector. Unlike the traditional "captured" agencies, which exist largely for the benefit of the regulated, these new agencies, according to Wilson, generally choose "stricter and more costly standards over more lenient, less expensive ones."[2]

But as their performance fell short of expectations, these agencies fell from grace. OSHA damaged its reputation by adopting wholesale and enforcing almost indiscriminately scores of private standards for everything from toilet seats to stepladders. The CPSC looked similarly foolish devoting substantial resources to regulating matchbook covers and swimming pool slides. Several studies have since documented the economic burden of other government regulations that became excessive. Government regulation has also proven to be time-consuming and adversary in nature. Most CPSC and OSHA rules end up in court; few survive the challenge.

Enthusiasm for protective regulation waned further in the wake of "deregulation." The original targets of this movement were independent regulatory commissions engaged in economic regulation (for example, regulation of prices or terms of entry) where there are powerful arguments against stifling competition in the name of the public interest. Promising to "get government off our backs," President Reagan advocated several controversial proposals to leave protective regulation to the private sector. But the "policy consensus" that facilitated deregulation in interstate trucking and airlines is lacking in the fields of environment, health, and safety regulation.[3] By some measures, there is continuing popular support for certain types of social regulation. By historical account, however, this support vacillates. There have been three waves of government regulation this century, and a fourth may be in the making.[4]

The options for the future are often described in stark terms, favoring either government or business. As Wilson describes the political prospects, "One [option], favored by liberals, is new constitutional or legislative devices that will allow the government to be both active and uncaptured…. The second, favored by conservatives, is to have the government do less, thus leaving a greater variety of decisions to the market and to private lawsuits."[5] These alternatives reflect a rigid conception of the public and private sectors. The public sector is cast as hierarchical and political, the private sector as decentralized and mar-

ket-based. But this conception does not do justice to the range of institutional arrangements available for protective regulation.[6] Rather, it obscures important similarities between public and private institutions, leaving no room for one of the most intriguing but misunderstood alternatives to government regulation: private standards.

This failure of political imagination has been observed elsewhere. In the context of social services, Lester Salamon notes that "the prevailing conception of the welfare state has left little room for a vibrant nonprofit sector or for a blossoming government-nonprofit partnership."[7] The underlying reasons are ideological. Conservatives tend to exaggerate the threat of government power; liberals minimize the accomplishments of the private sector. Yet, as Salamon demonstrates, nonprofit organizations play a much more important role in providing social services than is normally acknowledged.

The same is true in protective regulation. The prevailing conception of the regulatory state ignores significant activities in the private sector. Private standards are not even considered in many discussions of protective regulation. And when they are mentioned, ideology often clouds reality. Private standards have been promoted in the name of deregulation, even though they are obviously a form of regulation. But this position is based on ideology rather than on any specific understanding of how these obscure standards actually work.

The Vast Unknown World of Private Standards

Gas stoves, extension cords, x-ray equipment, and automobiles are among the thousands of items regulated in the United States by industrywide safety standards. Yet remarkably little is known about the institutions that generate the overwhelming majority of standards. These institutions, many will be surprised to learn, are private, not public. In the list above, only automobiles are subject to safety standards written by the public sector—and even so, private standards developed by the Society of Automotive Engineers play an integral part in the government's regulatory scheme. In significant product categories, such as gas and electric appliances, virtually all existing safety standards are developed by the private sector.

The National Bureau of Standards (NBS), recently renamed the National Institute of Standards and Technology,[8] estimated that there were thirty-two thousand private standards in 1983. The bulk of these regulate uniformity or interchangeability and are not particularly important or controversial.[9] The number infused with significant implications

for the public interest is probably in the thousands. These standards aim to promote social goods such as fire safety and product safety. Many are written by traditional trade associations—membership organizations with relatively homogeneous memberships. Others are written by little-known groups such as Underwriters Laboratories (UL) and the American Conference of Government Industrial Hygienists (ACGIH; a prominent private organization, despite its name). At least half of the top twenty standards-setters in the private sector are organized along professional lines or as "independent" entities (see table 1). More detailed background information about these private standards-setters appears in chapter 2.

Private standards raise many significant policy questions for government. First, public agencies must decide when (if ever) to defer to these standards or incorporate them into law. The Office of Management and Budget (OMB) issued a circular in 1982 to encourage federal agencies to use private standards, but the policy is vague and has not been implemented effectively.[10] Second, agencies must decide when and how to participate in private standards-setting. A controversial issue within the CPSC is whether government representatives should vote on private standards-setting committees. Third, government must consider how (if at all) it can improve private standards-setting. Finally, government must decide when (if ever) to ban private standards. The FTC and the courts have addressed this issue over the years in the context of antitrust law.[11]

The literature on private standards-setting is long on anecdotes but short on systematic analysis and evidence.[12] Public standards-setting, by contrast, has received far more scrutiny, even though the size of the undertaking pales in comparison to the private sector. The CPSC, for example, has adopted about a dozen product safety standards since 1973, several of which were struck down in court; UL, on the other hand, has over five hundred published safety standards currently in force.[13] Yet there are books, dissertations, and countless articles about the CPSC. The only published works about UL, a few scattered articles, were written mostly by UL staff members. David Hemenway's Industrywide Voluntary Product Standards provides a helpful analysis of the various types of private standards, but it says little about the "quasi-political" process through which these standards are developed.[14]

The Presumption Against Private Standards

Given their disputed, but potentially important, role in public policy, there is surprisingly little information about the actual performance of

| ||||||||||||||||||||||||||||||||||||||||||||||

private safety standards. Nevertheless, there is widespread belief that these standards are more lenient and are developed through procedures less formal and less solicitous of due process than those of government. Various conclusions might follow from this conventional wisdom. Informality might be favored over formality, as it increasingly is in the resolution of civil disputes. Leniency might also be favored, depending on whether government regulation is really as burdensome as often claimed. But those interpretations, however plausible, are rarely applied to private safety standards. Rather, suspicion of private regulation is so high that there is practically a prevailing presumption against using private standards for public purposes.

The Federal Trade Commission (FTC) was so concerned about private standards during the Carter administration that it proposed to regulate the entire enterprise. That effort was not ultimately successful, but neither was President Reagan's subsequent effort to increase public use of private standards. The OMB circular advising the use of voluntary standards "wherever possible" is ignored by agencies that harbor popular doubts about the desirability of private standards. Similarly, the CPSC, in the face of intense opposition, backed away from a proposal to "recognize" selected private standards.[15] The presumption against private standards stems from (1) the voluntary nature of these standards and (2) the political pressures that are thought to control their development.

The "Voluntary" Nature of Private Standards

Private standards are initially suspect because they appear to be "voluntary" in nature; at least they are frequently described that way. This label suggests the kind of decentralization intrinsic in market arrangements. In Albert O. Hirschman's useful terminology, it suggests the importance of "exit."[16] As an organizing force, exit can precipitate a distinct logic of institutional control. In the area of education, for example, Terry Moe and John Chubb argue that public schools, which respond more to politics (voice) than markets (exit), are "quite literally at a systematic disadvantage" compared to their private counterparts.[17] Because parents can remove their children from private schools, they argue, the teachers and administrators are more responsive than in the public sector.

Applied to the area of private safety standards, "exit" suggests a serious problem. To extend the analogy with education, manufacturers and other business interests apparently take the place of interested par-

ents as the primary influence on program administrators. These participants, seemingly concerned more about self-interest than about the interest of others, might "exit" if they do not approve of the regulatory product. In other words, they might refuse to participate in the process and boycott any standard developed in their absence. This suggests a bias in favor of the largest firms, those whose "exit" would most damage the enterprise.

A related hypothesis is that private standards-setters simply seek the "lowest common denominator." This downward pressure is thought to stem from rules requiring private standards to reflect a "consensus" of the participants. This does not usually mean formal unanimity, but the reality of private organizations is that "the fear of disintegration is frequently the decisive factor in the framing of governing institutions."[18] The implication is that the demands of organizational maintenance generally override the possibility that private standards will be more stringent than desired by nearly all the participants. As a result, George Eads and Peter Reuter have hypothesized, private standards-setters probably "water down" their safety standards to appease potential dissenters.[19]

These hypotheses seem most appropriate for trade associations, but they do not appear to fit a legion of other private standards-setters. Scores of so-called voluntary standards are actually coercive. They exist by demand on the part of more than just the regulated. Many of these standards have the force of law. UL standards, for example, are frequently incorporated into law through municipal building codes. Powerful nonlegal forces also compel compliance with various "voluntary" standards. Gas utilities generally will not install or service a gas appliance unless it is certified as complying with the safety standards of the American Gas Association (AGA) Laboratories. Major retailers such as J. C. Penney incorporate private safety standards into their purchase orders, helping to explain a popular observation by those familiar with private standards: "It is impossible to market an electric appliance in this country that is not UL-listed." These various forces call into question whether "exit" dominates private standards-setting. They also limit the application of George S. Stigler's theory that regulation exists primarily to satisfy demands of the regulated.[20]

Private Power and Public Safety

Recognizing that private standards cannot be dismissed as "voluntary" leads directly to larger concerns about the coercive use of private

power. As Grant McConnell argued in Private Power and American Democracy, it is "unreasonable to assert that private associations are both important to general policy and yet so unimportant that their political life may be ignored."[21] McConnell described as "orthodoxy" an "unstable amalgam of very different ideas" favoring the exercise of private power in America. While that "orthodoxy" certainly favors the basic elements of a vibrant market economy—McConnell wrote about the modern corporation, agriculture, and labor—the argument does not carry over to private safety standards. There is tremendous skepticism about private regulation in this country.

First, the United States has a strong legal tradition that embodies a liberty-based concern for the protection of individual interests against the exercise of "police powers." The legitimacy afforded private action in the business world, where social arrangements are more consensual than coercive, simply does not extend to actions perceived as "regulatory." Concerns about the due process of private standards-setting are widespread. These concerns were fundamental to the FTC's effort to regulate private standards-setters. Lacking the constitutional order of public government, these groups appear particularly vulnerable to Robert Michels's "iron law of oligarchy"—the tendency of organizational leaders to acquire and promote interests different from those of their members.[22] The tendency of private organizations to develop "internally nondemocratic and bureaucratic structures" is "generally accepted as fact by social scientists."[23] Although the FTC did not adopt the process-based regulations, it retains legal jurisdiction, and its attorneys retain heightened interest, in pursuing complaints concerning private abuses of due process.[24]

The second argument against private standards is more substantive. The political critique of pluralism suggests that when private groups dominate the policymaking process, the results are rarely (if ever) in the public interest. "The most entrenched, the best organized, and frequently the oldest" interests are likely to benefit most from the resulting policies.[25] This criticism need not imply bad motives or exclusionary practices on the part of private standards-setters. Even organizations that encourage participation of various groups are unlikely to hear from some interests. The "logic of collective action" suggests that consumer and other diffuse interests will often be underrepresented, whatever the forum.[26] These interests might be galvanized effectively (but temporarily) by a catastrophe, but in the long run the concentrated interests of the regulated are likely to prevail.

The argument is familiar in the public sector, where agencies are often thought to favor the interests of the regulated. Based on observations about the Interstate Commerce Commission, the Civil Aeronautics Board, and the Federal Communications Commission, for example, Grant McConnell argued in 1966 that "accommodation" with private interest groups tends to "eliminate public values from effective political consideration."[27]

Theodore Lowi has argued more recently that the "parceling out" of public policymaking to private interests is "co-optive" and destructive of public values. Private safety standards appear to be the ultimate extension of this phenomenon. Lacking the presence of outside interests, private regulatory institutions seem nothing more than a variation of the fox guarding the chicken coop. Lowi makes specific reference to private standards in the second edition of The End of Liberalism, condemning these arrangements as "prime examples of the continuation and reinforcement of 1960s liberalism applied to public policy."[28]

Beyond "Capture" Theory: Toward an Institutional Perspective

But private regulation, like public regulation, varies in so many respects, internal and external, that no single theory fits all forms. Just as capture theory has limited application in the public sector, particularly in the area of protective regulation, there is reason to question its universal application in the private sector. The politics of private regulation appear to be far more complex than capture theory admits. The mixture of motives and interest groups in the private sector is wide-ranging and unpredictable. Internal factors, such as administrative procedures and organizational self-interest, further complicate the picture. Each suggests reasons why capture theory apparently fails to chart the most important differences between public and private standards-setters.

Who Benefits from Private Safety Standards?

Private standards-setters are widely assumed to be "captured" by business interests. Suggesting otherwise would, under this view, be as naive as indulging the notion that public agencies simply carry out their statutory charge to act "in the public interest." But developments in the public sector suggest that capture theory does not fit protective regulation nearly as well as it fits economic regulation. The classic state-

ments of capture theory—Samuel P. Huntington's "administrative marasmus," Marver Bernstein's "life-cycle theory," and Stigler's "theory of economic regulation"—stem from agencies that regulated prices or terms of entry.[29] There is little justification for such regulation, the kind long performed by the Interstate Commerce Commission ("the most studied of all agencies" when McConnell and Lowi wrote about government regulation).[30] But protective regulation is different. It is economically defensible in various (arguably frequent) instances of market failure.[31] And, at least in the public sector, protective regulation does not come about through the demands of business. More often it is adopted over their objections. "Only by the most extraordinary theoretical contortions," Wilson concluded, can this regulation be explained "by reference to the economic stakes involved."[32]

Protective regulation in the private sector is similarly complex. Business interests are neither unitary nor necessarily opposed to the public interest. Some forms of private standards-setting, typically those sponsored by trade associations, are controlled entirely by the regulated. Others are more independent, offering services such as "third-party certification." The mission of these organizations resembles those of the public agencies charged with protecting health and safety. Their status is unclear, however, and this lack of clarity has given rise to several disagreements about motives. UL lost a legal battle with the Internal Revenue Service in 1943 when a federal court decided that "testing for public safety" is a business, not a charitable undertaking.[33] A private standard developed by the National Sanitation Foundation was upheld in a recent case partly because the court considered the organization to be "independent."[34] How to characterize the American Society of Mechanical Engineers (ASME) was the source of strong disagreement in a recent Supreme Court case, with one side calling it a "scientific" group and the other side alleging it is "dominated by commercial interests."[35]

To be sure, there is a rich tradition of using "self-regulation" to stifle competition. This includes standardization of sizes and shapes, practically a prerequisite to effective price-fixing.[36] But safety standards are different. Granted there are some anticompetitive ones masquerading as safety standards, but there are also genuine safety standards that, although not necessarily as strict as what government would adopt, certainly benefit the diffuse interests of consumers.

These private standards-setters do not fit easily into the existing understanding of private organizations. In their landmark study of formal organizations, Peter Blau and W. Richard Scott classified organi-

zations "on the basis of the cui bono —who benefits."[37] In his book Who Profits, Robert Leone suggests looking at regulation in a similar way.[38] Either way, private standards-setters are far more complicated than generally appreciated. In Blau and Scott's terms, private standards-setters are likely to be considered "mutual-benefit associations," organized primarily for the benefit of membership. But that analysis fits the trade associations much better than the "independent" organizations. The membership of, say, the National Fire Protection Association is so large and diverse that the "mutual-benefit" theory clearly does not fit. The members are not the primary beneficiaries of most standards. And many organizations, such as Underwriters Labs, do not even have members.

These groups might be considered "service organizations" because they have clients. But that description is also inappropriate, because product testing and certification appear to be directed at third parties, including insurance companies, wholesale buyers, and individual consumers. This leaves the most nebulous category of all: the "commonweal" organization, whose prime beneficiary is the public at large. While this term undoubtedly describes some private standards-setters, it is not clear whether "commonweal" private standards are likely to be better or worse than the public alternatives.

Several political scientists have condemned private standards in any case. Lowi declared private safety standards guilty by association with the old National Recovery Administration (NRA). Calling these standards "indistinguishable" from the old NRA codes, Lowi marveled that "there is so little suspicion as to their constitutionality" under the nondelegation doctrine.[39] Others have invoked the ghost of Herbert Hoover—the engineer turned secretary of commerce intent on a grandiose plan of economic "standardization"—to belittle private standards.[40]

These arguments are not convincing. In contrast to Lowi's interpretation, Donald Brand has recently argued that "ideology and the institutional interests of the state played a more important role in determining the behavior of those administrators than special interest demands."[41] Moreover, just as it would be inappropriate to judge the Environmental Protection Agency based on the performance of the Interstate Commerce Commission, it is inappropriate to judge private safety standards as if they were akin to the NRA's "codes of fair competition" (in other words, economic regulation).

Lowi's argument also misrepresents the role of the public and private sectors by suggesting that government is preeminent in protective reg-

ulation. By framing his argument in terms of "delegation," Lowi implies that these functions are somehow inherently public. This conception is not supported by history. The private sector was in the business of product safety decades before the Consumer Product Safety Commission was created in 1972. The American Gas Association Labs started regulating gas appliances in the 1930s, and Underwriters Laboratories was certifying electrical equipment before the turn of the century.

These arrangements are far more complicated than capture theory admits. Undoubtedly, some private standards-setters are mainly self-serving. But others probably promote the public interest to a significant degree. When OSHA adopted hundreds of private standards, the problem was not that they were private; it was that the agency acted indiscriminately.[42] Some of those standards were essentially defunct, like old statutes never removed from the books. Others were more desirable. Unfortunately, OSHA did not distinguish between the two. In 1988, however, without any measurable opposition, OSHA adopted a more carefully selected group of private safety standards.[43] Certainly the public benefits to some extent from these standards, although the magnitude of the benefit and its corresponding cost must be examined before reaching any broader conclusions.

Bringing the Bureaucracy Back In

A second major problem with existing theories of private standards-setting is that they do not account for organizational interests or administrative procedures. Agencies should not be "mistaken as passive tools yielding to the strongest pressure of the time."[44] Organizations have their own interests, although these are often overlooked in theories that emphasize compromise among outside interests. Bringing the bureaucracy back into the consideration of private standards challenges the conventional wisdom in two ways. First, it demonstrates that private administrative law is similar in many ways to traditional administrative law. Second, it identifies several unexpected manifestations of organizational self-interest.

Private Administrative Procedure . The rules of administrative procedure, the stuff of administrative law, are recognized as an important influence on agency decisionmaking in the public sector. Although the content of administrative law is controversial, it is widely assumed that the tradition of constitutionalism it reflects sets the public sector apart

from the private. By affording certain due process protections, enforcing notions of interest representation, and holding agencies accountable through an appeals process, administrative law shapes and legitimatizes agency decisionmaking. Private forms of governance, by contrast, are more consensual, minimizing the rule of law and, according to Lowi, favoring large, well-organized groups.

But the private sector is not without administrative rules and legal norms. In fact, there is a surprising degree of similarity in procedural requirements in the public and private sectors. The precepts of due process are enshrined in the by-laws of most private standards-setting organizations. Simple notice and comment procedures are commonplace. And the opportunity to appeal exists in many organizations. The Board of Standards Review, for example, hears appeals concerning any of the thousands of standards sponsored by the American National Standards Institute (ANSI). Committee membership in several private organizations is subject to rules against "domination" by any single interest. Some private standards-setters encourage outside groups, including consumers, to participate in their proceedings. The extreme example, the American Society for Testing and Materials (ASTM), even pays such groups to participate in the development of certain standards—a practice that has been discontinued in the public sector.

This is not to say that various private organizations protect individual interests to the same extent as public organizations; only that they apparently do more than is generally recognized. Of course, more is not necessarily better when it comes to procedural "protections." As Ronald Braeutigam and Bruce Owen point out: "This jurisprudentially laudable set of constraints on agency behavior has an interesting side effect, which is the creation of substantial delays and legal expense."[45] Such costs might be worthwhile. But, as Lawrence Bacow observes, divisive proceedings might hinder compliance.[46] Overly formal proceedings might also limit "the rich set of informal contacts" that would otherwise enhance decisionmaking.[47] Therefore, the private sector might even hold an advantage over the public if its administrative procedures strike a better balance between providing meaningful procedural protections and minimizing the undesirable side effects of due process.

Organizational Self-Interest . Conceiving of standards-setting solely in terms of the regulated also overlooks the recognized importance of organizational self-interest. Agencies do not just respond to exterior

pressures; they have interests of their own. Although there is no clearly articulated theory of organizational self-interest in the public sector, it is widely assumed that the interests of private regulators diverge significantly from the public interest. Much has been made of Michels's "iron law of oligarchy," the tendency of organizational leaders to acquire and promote interests different from those of their members. McConnell went so far as to argue that "the sweep of [Michels's] work extends by implication to all organizations in which membership could be said to exist."[48] Michels's conclusions stem entirely from a 1913 study of political parties in Germany, however, and in all likelihood the operation of this "iron law" varies significantly with such variables as organizational purpose and structure, not to mention larger differences in political culture and history.[49] Even if Michels's hypothesis is fitting, what ultimately matters is the nature of the interests pursued by the leadership of private standards-setters.

One of the few studies of private safety regulation, Michael Hunt's examination of the Association of Home Appliance Manufacturers, suggests that the leadership might pursue policies more enlightened than those favored by the membership. Hunt found that the AHAM staff had "a substantially different set of preferences from the member companies" and used it to achieve "stricter" results than would have been supported by the membership![50] Steven Kelman's comparison of public regulation of the workplace in the United States and Sweden is similarly suggestive. Kelman concludes that these two seemingly different regulatory regimes produce surprisingly similar outcomes. He attributes this largely to the influence of safety professionals.[51] Wilson's study of public regulation concludes that the motives of various types of government employees help explain outcomes that cannot be explained by capture theory. Similar influences probably exist in the private sector. To the extent that they do, private standards are more desirable than generally recognized. In short, Michels could be right about the significance of organizational self-interest, but Lowi could nonetheless still be wrong about the undesirable nature of the resulting outcomes.

There are several other reasons aside from the influences of professionalism why private standards-setters might adopt standards much stricter than expected. One is the desire to forestall government action. This incentive might actually lead the private sector to adopt stricter standards than government would have done.[52] Another possible reason is liability law. In the case of product safety standards, for example,

strict standards may minimize liability costs or reduce the cost of liability insurance.

This is not to say that private standards are generally better or worse than public ones. Insufficient information is available to reach a conclusion. There are reasons both to doubt and to believe the conventional wisdom about public and private regulation. What is needed is more detailed information about the similarities and differences between standards-setting in the public and private sectors.

Research Goals and General Findings

This study seeks to provide the basis for a better understanding of the relative merits of public and private standards-setting in the area of safety regulation. Given limited knowledge of private-sector efforts, however, the first goal is to determine how private organizations actually work. What Wilson said about studying public regulation is equally true of private: "There is a need to go beyond an account of the newsworthy scandal to an exposition of how [agencies] ordinarily operate."[53] This inquiry is well suited to the case-study method. Two lines of analysis are suggested in the literature. The first concerns administrative law and procedures. Little is known about how private organizations actually achieve "consensus," respond to negative comments, or handle appeals. Proponents of private standards claim these procedures work well; critics charge they paper over fundamental flaws in private decisionmaking. An analysis of specific cases should shed some light on this dispute. The other obvious avenue for inquiry is political. Critics argue that the interests represented in private standards-setting are heavily biased in favor of business. This hypothesis is plausible, but, as indicated above, there are also reasons to doubt it. The case-study approach allows a detailed examination of the nature and balance of participating interests in a specific context.

The ultimate aim of this study is to evaluate the relative performance of public and private standards-setting. How well does each sector regulate safety? This study consists of four pairs of case studies. In each instance, both the public and private sectors have adopted safety standards in the same general area, and the study concentrates on organizational differences between the two sectors. The form of inquiry is decidedly institutional. Its main contribution is in identifying the comparative institutional advantages of the two systems.

Looking ahead to the analysis and conclusions, these case studies suggest that the difference between public and private standards-setting is not just a matter of degree, but one of kind. The analysis reveals important differences in how public and private standards-setters (1) estimate costs and benefits, (2) resolve philosophical questions about the appropriate scope of safety regulation, and (3) act over time and in the context of a larger regulatory program. Is the public or the private approach generally better? No simple answer to the question is possible, because the two sectors do not only favor different outcomes; they have different ways of looking at problems as well.

The analysis of outcomes partially confirms the conventional view that public standards are stricter than private ones and more prone to overzealousness. But there are contrary indications as well, suggesting that the private sector is more diverse than often presumed. Although the range of the interests represented on most private committees is limited by the absence of bona fide consumer representatives—an interest not necessarily better represented in public proceedings—the cases identify several important, but unappreciated, advocates of safety in the private sector. On occasion these forces combine to exhibit a surprising tendency toward strictness. Private standards should not, therefore, be rejected on the argument that they are intrinsically underprotective.

The differences between public and private approaches are not just in what should be done about a problem, but in whether anything should be done. Some "solutions" that are never seriously considered by one sector are routinely favored by the other. For example, public agencies are more willing than private ones to select early compliance deadlines, require use of unproven technologies, and regulate in a manner that interferes with traditional notions of managerial discretion. But these differences do not all cut along ideological lines. In surprising ways the private philosophy also encompasses public safety goals. Two institutional features appear to shape these regulatory philosophies: professional norms and the regulatory environment.

The significance of the former was suggested by Wilson, whose study of public regulation notes that professionals in different fields "often have distinctive ways of thinking about problems." This is particularly significant in comparing public and private standards-setters, because engineers dominate most private organizations, while lawyers play a leading role in the public sector.

The law is also a powerful external influence that constrains decisionmaking in the two sectors. Only private standards-setters are subject to the antitrust laws, and they frequently cite these laws as a reason for taking various actions. Liability law is seldom cited as an official reason for doing anything in the private sector, but the case studies suggest it is a more significant factor than antitrust law in explaining regulatory behavior. Liability concerns help explain why certain provisions are vague while others are relegated to an appendix. More generally, liability law seems to explain the reluctance of the private sector to address issues of consumer misuse or embrace certain new technologies. Public agencies, on the other hand, are subject to more frequent and intrusive judicial review of their regulatory decisions. These differences in regulatory environment help explain other differences in regulatory philosophy.

At least as important as these static differences is how the organizations change over time. Aaron Wildavsky has stressed the importance of "resilient" approaches to safety regulation.[54] Others have emphasized the advantages of "flexibility" and "responsiveness."[55] These concepts place standards-setting in an evolutionary context. What matters is not so much how individual cases are resolved, but how results change over time. Again, the case studies suggest important difference between the public and private sectors. Private standards-setting is prospective and ongoing, while public efforts tend to be corrective and singular. Private standards-setters tend to intervene relatively early in the life cycle of an issue, adjusting the subsequent standard over time. Public standards-setters, by contrast, are likely to get involved later in time, often after a major disaster, and to adopt a "one-shot" standard that is not subsequently revised.

Chapter 12 offers several suggestions on how to take advantage of these differences. One approach is for the public sector to stress "public" values. In other words, it should emphasize strategies shunned by the private sector. Second, government should identify niches where public standards are likely to complement private ones. A particularly promising strategy is filling "holes" in private standards. Finally, the importance of alternative policy instruments must not be overlooked. Standards-setting in both sectors is affected by a variety of "external" factors that are subject to influence by government action. Several of these alternative policy instruments hold the promise of improving standards-setting in ways that could never be mandated directly. For ex-

ample, altering product liability law and improving the education of engineers could both lead to significant improvements in standards-setting. Recognizing these subtle influences and pursuing strategies that build on the complex interaction of public and private safety standards is the key to an intelligent and productive standards policy.

Two

Background and Research Design

The universe of private standards is massive and mysterious. There are literally tens of thousands of these uncelebrated standards. In contrast, public standards seem better understood and more commonplace. Agencies such as the Consumer Product Safety Commission, whose standards often generate significant media attention, have been the subject of countless studies. Most private standards-setters operate in relative obscurity. This chapter presents some general background about both universes, public and private. It also provides a précis of several important, but not well known, private standards-setters. The chapter concludes with an explanation of the research design of this study, consisting of four comparative case studies of setting safety standards.

Private Standards and Public Interests

According to the most extensive directory of standards-setting organizations, compiled in 1983 by the National Bureau of Standards, based on information submitted by private organizations, approximately 420 nongovernment organizations maintain thirty-two thousand standards in the United States.[1] These standards facilitate commerce in various ways, but most are not particularly important to public policy. Some set forth definitions such as size of screw threadings. Others facilitate the interchangeability of items such as flashlight batteries and automobile parts. An ANSI standard specifies the minimum requirements for the

permanence of paper for printed library material (see the copyright page of this book). A small portion, consisting of at least one thousand standards, are infused with more significant implications for the public interest.

The largest component of this group involve matters of public health and safety. Private standards affect the public interest in other areas, of course, such as finance and communications. For example, the Financial Accounting Standards Board, an entirely private organization, develops the influential Statements of Financial Accounting Standards (SFASs) that form the bases of "generally accepted accounting principles."[2] Similarly, the National Advertising Review Board and, to a lesser extent, the National Association of Broadcasters privately regulate advertising. But this study focuses on private safety standards, a field that roughly parallels the distinct domain of public regulation often placed under the rubric of "environment, health, and safety" regulation.

The subset of private standards that directly concern public health and safety is fairly well delineated. The best measure comes from the American National Standards Institute, an organization that certifies standards written by other groups. For reasons discussed in later chapters, most, but not all, private standards-setters seek ANSI approval. ANSI classifies approximately 900 of its 8,500 certified standards under the rubric of "Safety and Health."[3] These standards cover a fantastic array from the obviously important (Criteria for Accident Monitoring Functions in Light-Water-Cooled Nuclear Reactors) to the seemingly trivial (Safety Standard for Christmas Tree Lights). Some of ANSI's safety and health standards are procedural (Storage and Handling of Mixed Fluid Fertilizers); others are substantive (Safety Requirements for Baling Equipment). A few are massive in scope. The Boiler and Pressure Vessel Code, for example, fills twenty-four volumes. Others take up just a page (Safety Standard for Agricultural Equipment), although obviously there is no way to tell from the name alone.

The ANSI list omits some significant private organizations involved in environment, health, and safety regulation. Building code organizations, for example, play a critical role in public safety. Building codes, which vary by region and by type of construction, make reference to countless ANSI standards. But the codes themselves are not certified by ANSI. Nor does ANSI list many safety standards developed in connection with the insurance industry. The Factory Mutual Research Corporation, for example, develops loss control standards for industrial and commercial policyholders insured by the Factory Mutual System. This

extensive private regulatory system, founded in 1835, consists of hundreds of engineers and technicians, along with a cadre of inspectors who implement FM's "Approval Standards." In short, the ANSI estimate of nine hundred private "health and safety" standards includes many, but not all, of the relevant standards.

Private standards-setting occurs under several institutional arrangements. Four basic forms of organization account for nearly all private standards: (1) trade associations, (2) professional societies, (3) general membership organizations, and (4) third-party certifiers. These organizations have different forms of governance, and they rely on a variety of administrative procedures. But a few core concepts permeate these organizations: one is "consensus" decisionmaking; the other is due process.

Organizational Forms of Private Standards-Setting

Trade associations are probably the best known and the least trusted form of private standards-setting. Since trade associations are created to advance the interests of their (usually homogeneous) memberships, it is widely assumed that their standards will be anticompetitive or otherwise against the public interest. But only some trade association standards have significant implications for the public interest. Most facilitate commerce in a rather mundane fashion. The Diamond Walnut Growers, for example, develop standards for the size, color, and grade defects for in-shell walnuts. Other trade associations develop a full array of such relatively innocuous standards. The American Petroleum Institute, for example, maintains 350 standards concerning the transportation, refining, production, measurement, and marketing of petroleum products. Trade association standards are usually financed directly by the membership, reinforcing the concern that narrow private interests will capture the process. But trade associations account for only a small portion of ANSI-certified health and safety standards.

Professional societies and general membership organizations bring together a broader spectrum of participants than trade associations. Rather than being tied to one economic interest, the memberships of these organizations are diverse. There are numerous professional societies organized around the specialties of engineering. For example, the Society of Automotive Engineers (forty-four thousand members) maintains over a thousand standards for ground vehicles and several thousand more for aerospace applications. Similar organizations include the

American Society of Agricultural Engineers (167 standards), the American Society of Heating, Refrigeration, and Air-Conditioning Engineers (60 standards), and American Society of Lubrication Engineers (22 standards).[4] These organizations generally develop technical standards (for example, definitions, specifications, and tolerances), few of which are very controversial or significant to the public interest.

Membership organizations are broader in constituency, but not necessarily in purpose. They are more open than trade associations, often including participants from various professions and competing aspects of industry. The American Society for Testing and Materials, often called "the world's largest source of voluntary consensus standards," has almost thirty thousand members and seven thousand standards. Most of its standards resemble those of an engineering society. In other words, very few have significant implications for public policy. The National Fire Protection Association (NFPA), by contrast, has a similar number of members and about one-thirtieth the number of standards (approximately 250), but all NFPA standards concern public safety. One important feature that membership organizations have in common is loose reliance on the market demand for their standards: 77 percent of ASTM's budget comes from publication sales; NFPA derives two-thirds of its income from the sale of standards.

The final form of private standards-setting is so different from the others that it is often given a separate name: certification.[5] "Third-party certifiers" test products against standards. They collect a fee for certifying compliance, which is usually signified by affixing a label or seal to the product. While some testing laboratories rely on standards developed by other organizations, the most significant product certifiers are also standards-setters. The most prominent of these organizations is Underwriters Laboratories, a nonprofit organization with the motto Testing for Public Safety. In-house engineers develop UL's standards. Less well known organizations engaged in third-party certification include the National Sanitation Foundation (which certifies restaurant equipment) and the International Association of Plumbing and Mechanical Officials (a model building code organization that certifies compliance of various products with the code). Some trade associations, such as the Association of Home Appliance Manufacturers and the Snowmobile Safety and Certification Committee, provide specialized certification services, which can generate significant income for them.[6]

A few administrative procedures characterize almost all of these organizations. One is "consensus" decisionmaking. The other, surpris-

| ||||||||||||||||||||||||||||||||||||||||||||||||

ingly, is due process. These tenets form the basis for ANSI certification of private standards and are incorporated into the by-laws of many private standards-setting organizations. Although the extent of due process protections varies by organization, and the real-world implications of "consensus" decisionmaking are not clear, these concepts obviously play an important role in how these organizations define themselves.

Profiles of Prominent Private Standards-Setters

Lacking a more detailed description of the universe of private safety standards, perhaps the best way to understand this territory is through its major landmarks. Some of the most prominent private standards-setters in the field of public safety are described briefly below. These organizations vary significantly in age and size (see table 2). Four of them—ANSI, AGA Labs, NFPA, and UL—are examined in detail in later chapters.

ANSI . The American National Standards Institute is unique among these groups, acting as an overall coordinator and certifier of the so-called voluntary national standards system. It is the trade association of the standards-writing industry. ANSI does not write standards. Other organizations, including ANSI committees—groups "accredited" by ANSI—submit their standards for approval as American National Standards. There are approximately 8,500 ANSI-approved standards (1,000 of which were developed by ANSI committees). The requirements for ANSI certification, discussed later in this chapter, are essentially procedural, not substantive. The Board of Standards Review hears complaints from anyone who objects to certification of a "national consensus standard." Appeals are infrequent, except in the area of "health and safety." Approximately 900 ANSI-certified standards are in this category. ANSI's membership consists of industry representatives and standards-setting organizations (including professional and technical societies, trade associations, and government agencies).

ACGIH . The American Conference of Government Industrial Hygienists publishes an annual compilation of Threshold Limit Values—recommendations on airborne contaminants and physical agents in workplaces—for approximately six hundred chemical substances. These values influence industrial practice in the United States and in a host of countries abroad. Despite the implication of its name, ACGIH is a private organization with no formal links to the public sector. The organization was founded in 1938 by federal, state, and local health officials. Its committees now include academics and industry representatives. A recent study of "Corporate Influence on Threshold Limit Values" concludes that there are "104 substances for which important or total reliance was placed on unpublished corporate communications."[7]

AGA Labs . The American Gas Association Laboratories, a division of the larger trade association, is sometimes referred to as "the UL for gas appliances." Founded in 1918, AGA Labs provides third-party certification for all gas appliances. It currently maintains sixty-five standards. Unlike UL's, these standards are not developed by in-house engineers. They are developed by ANSI-sponsored committees consisting of various representatives, largely from industry.

ASME . The American Society of Mechanical Engineers is a nonprofit educational and technical organization with 110,000 members

and nearly six hundred active standards. ASME's reputation is based almost entirely on one standard: the Boiler and Pressure Vessel Code, a compilation of safety and performance requirements for power and heating boilers, nuclear reactors and power plants, and pressure vessels, which is widely incorporated into law throughout the United States and Canada. ASME's image was tarnished in 1983 when, after it refused to settle an antitrust case involving a blatantly anticompetitive interpretation of the Boiler and Pressure Vessel Code, the Supreme Court upheld a $9.5 million judgment against the organization. ASME argued that it should not be responsible for the acts of volunteers acting in bad faith.[8]

ASTM . The American Society for Testing and Materials, founded in 1898, is a nonprofit organization "to develop standards on characteristics and performance of materials, products, systems, and services." A staff of two hundred oversees the maintenance of 7,218 standards, most of them standards for uniformity. A few committees act in a more overtly regulatory fashion. The F-15 Committee (consumer products) has developed a dozen standards for products such as high chairs, cigarette lighters, and bathtub grab bars. ASTM standards are written by "volunteer" committees and subject to the approval of ASTM's thirty thousand members. ANSI has long been an organizational rival of ASTM'S. The organizations trade allegations of "turf grabbing," and ASTM no longer submits its standards for certification as American National Standards.

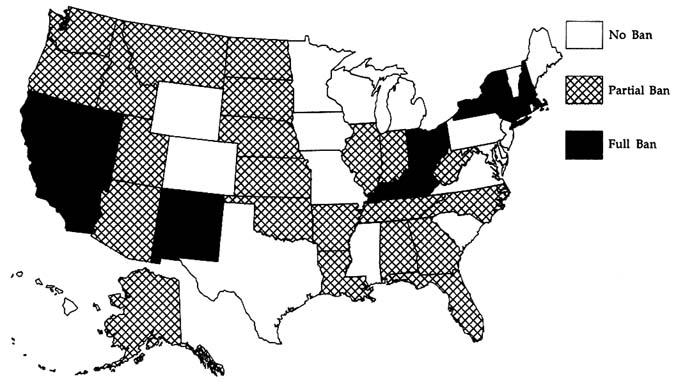

Building Code Organizations: ICBO, BOCA, SBCCI . Building codes, enforced by local building inspectors, are one of the most visible forms of government safety regulation. They are largely written, however, by a complicated web of overlapping private standards-setters. Four model code organizations dominate the field. The International Conference of Building Officials (ICBO) promulgates fourteen comprehensive codes covering various aspects of construction. These codes make reference to nearly one thousand ASTM, UL, NFPA, and ANSI standards. The best known, the Uniform Building Code, is enforced in jurisdictions from Michigan and Indiana to Alaska and Hawaii. The Southern Building Code Congress International (SBCCI) and the Building Officials and Code Administrators International (BOCA) each promulgate similar sets of building, plumbing, mechanical, gas, fire, and housing codes. The SBCCI codes have been adopted in over 1,600 communities in the Southwest, South, and Southeast; the BOCA codes

cover fourteen states and 3,000 local governments in the East and Midwest. Finally, the Council of American Building Code Officials (CABO), created by the three major building code organizations, attempts to coordinate activities, particularly with regard to product certification. There are myriad other actors in the field of building codes, many providing specialized standards that are incorporated into building codes. The CABO One-and-Two Family Dwelling Code, for example, mandates, among other things, compliance with ANSI Z21.11.2 (the private safety standard for unvented gas space heaters, examined in chapter 6). The International Association of Plumbing and Mechanical Officials, author of fifty-seven product and installation standards, develops the Uniform Plumbing Code, adopted in the building codes of over 2,500 jurisdictions.

NFPA . The National Fire Protection Association is a membership organization similar to ASTM. "Volunteer" committees write the 260 NFPA codes and standards, and the membership votes en masse at semiannual conventions. NFPA has over thirty-two thousand members, including architects, engineers, firemen, manufacturers, and representatives of insurance interests, labor, and government. NFPA standards are published as the National Fire Codes in a multivolume set consisting of over twelve thousand pages. Various NFPA standards are referenced by OSHA, the Coast Guard, the Veterans Administration, and the Department of Housing and Urban Development. Its best-known codes, the National Electric Code and the Life Safety Code, have the force of law in most jurisdictions. Other standards cover the fire risks at nuclear power plants, airports, storage tanks, and grain elevators.

UL . The primary business of Underwriters Laboratories is product safety certification. UL evaluates products and monitors the quality control of their production. Manufacturers pay for the service, and if their products comply, they are entitled to display the UL label. There are other testing laboratories—most prominently, the American Gas Association Laboratories in the field of gas appliances—but many simply certify compliance to UL standards. The most important feature of UL is that it writes the standards it uses in testing. There are over five hundred published UL standards, covering such diverse products as microwave ovens, life preservers, kerosene heaters, fire extinguishers, and automated teller systems. UL maintains membership in five hundred committees of other private standards-setting organizations.

The Universe of Public Safety Standards

Public standards seem both more visible and more controversial than private ones. In the areas of environment, health, and safety, most of the federal agencies that develop standards are practically household names: EPA, OSHA, FAA, FDA. Other federal agencies, involved in similar missions, have less name recognition, but they are nevertheless well known for what they do. The National Highway Traffic Safety Administration (NHTSA), the Nuclear Regulatory Commission (NRC), and the Consumer Product Safety Commission, for example, all write safety standards in areas where public regulation is widely recognized and generally supported.

These agencies vary considerably in size. It is difficult to compare the number of standards they develop because public standards usually come in packages, rather than individually. Unlike the private sector, where separate committees develop discrete standards on a project-by-project basis, public agencies take a range of actions from the adoption of single standards to the implementation of complex statutes. The Code of Federal Regulations is not divided by individual standards. For example, the safety standards of the NRC comprise 850 pages in one title of the code, which by one count represents approximately 350 standards. In contrast, the subchapter of the code concerning biological products regulated by the FDA accounts for approximately 325 standards.[9] Lacking a comparable measure of actual standards-setting activity, the relative size of these agencies can roughly be gauged by their budgets and staff (see table 3).

These agencies also vary considerably in age, reflecting the three waves of public regulation this century. The Food and Drug Administration (FDA) and the Federal Trade Commission (FTC) are the oldest, reflecting the Progressive Era, when federal regulation began. The FDA was created in 1906, the FTC in 1914. The Federal Aviation Administration (FAA) evolved from a New Deal agency, the Civil Aeronautics Board (1938), created along with a host of agencies primarily engaged in economic regulation (for example, the Securities and Exchange Commission and the National Labor Relations Board). The most controversial federal agencies are also the youngest. These agencies spearhead the "new social regulation" movement, a grandiose agenda of environment, health, and safety objectives adopted about twenty years ago. The most prominent are the EPA, OSHA, NHTSA, NRC, and CPSC. Although other strategies would be possible, these agencies generally favor

| ||||||||||||||||||||||||||||||||||||

"command and control" regulation, which relies on standards, inspectors, and penalties to achieve social ends. One important feature common to all of them is the Administrative Procedures Act (APA), which describes two kinds of rulemaking, formal and informal. Most agencies favor the latter but implement it in a "hybrid" fashion that incorporates some due process protections beyond those demanded by the APA.[10]

Agencies concerned with environment, health, and safety regulation account for only a small portion of all federal standards. By one count, the federal government maintains more standards than the private sector. According to the National Bureau of Standards, there were forty-nine thousand standards in 1983.[11] As in the private sector, however, most of these are not particularly weighty. The overwhelming number are procurement standards adopted by either the Department of Defense (38,000) or the General Services Administration (6,000). The number of federal standards with significant implications for the public interest is minuscule by comparison.

In most areas involving the environment, health, or safety, there are far more private standards than public ones. Take consumer product safety, for example. Hundreds of private standards are developed by UL alone. In contrast, the relevant federal agency, the CPSC, had twenty-one active standards in 1984, many of which were carry-overs from old statutes.[12] A few others seem absolutely frivolous. Not coincidentally, these standards (matchbooks, swimming pool slides) were overturned in court. This leaves only a handful of safety standards actually devel-

oped by the CPSC—most prominently, standards for lawn mowers, gas-fired space heaters, electrical toys, and citizens band base station antennas.

In most areas that government seeks to regulate there are already so many private standards that interaction between the two sectors is inevitable. Model codes and use codes, including most standards developed by the National Fire Protection Association, contain repeated references to "the authority having jurisdiction." In other words, they are written in anticipation of adoption by government (usually at the local level). The federal agencies that regulate safety issues are also intertwined with the private sector. Many federal agencies rely directly on private standards to accomplish public purposes. The FDA, for example, has adopted over three hundred standards from private organizations such as ASTM, the American Public Health Association, and the Association of Official Analytical Chemists. The National Highway Traffic Safety Administration, by contrast, uses private standards (developed by the Society of Automotive Engineers) for test methods and other largely technical matters, while leaving basic safety questions to the public realm. Most agencies participate in private standards-setting activities. The CPSC, which originally had a procedure for private organizations to "offer" standards for agency adoption, has participated in the development of hundreds of private standards. The Nuclear Regulatory Commission participates on more than 150 private standards committees. Although interaction and coexistence prevail, there remain distinct areas of public regulation.

Research Design

Making a direct comparison of public and private standards-setting practically requires that the two sectors be active in the same area. Otherwise, whether outcomes or procedures are evaluated, case studies in either sector will leave the same lingering question: compared to what? The criterion of economic efficiency, often a useful benchmark, probably has limited potential. "Determining the proper level of product safety is next to impossible," note Eads and Reuter in the introduction to their case studies of corporate safety efforts.[13] Without independently conducting cost-benefit analyses, it is doubtful that existing information will facilitate anything more than a crude analysis of outcomes.

An obvious answer to the benchmark problem is to compare the

private sector directly with the public. After all, the most important public policy questions about private standards are comparative. What really matters in assessing possible government action is how that action compares to the actual alternatives. One can only speculate whether public standards would actually be stricter in the thousands of areas presently regulated exclusively by private standards. But in the areas where public and private efforts overlap, outcomes can be evaluated comparatively.

If appropriate "pairs" can be found, the comparative approach has two obvious advantages. First, it solves the benchmark problem. Without a comparative framework, it is difficult to imagine how to evaluate either public or private standards in a fashion that will shed light on the other sector. The exercise would be entirely hypothetical: guessing what the other sector might have done. Second, the comparative approach might also facilitate broader generalizations by "controlling" for the idiosyncrasies of issues. It is frequently alleged that general theories of regulation are fruitless because circumstances such as industry profitability and structure, the quality of available information, and the mixture of political interests vary significantly by issue. A related argument, relevant to the study of public and private regulation, is that only certain types of issues are regulated by government. Government, the argument goes, regulates the issues that industry will not, making the public cases unique. Both of these arguments fade if the public and private sectors are active in the same area.

There are drawbacks, however, to studying only those cases in which public and private efforts can be paired. First, the universe of possible cases is very small. Public and private standards rarely regulate the same things. Moreover, when there is overlap, there is the attendant danger that the effects of their interaction will obscure the influences that might otherwise prevail. In other words, the observed outcomes might reflect "strategic behavior" more than they reflect the indigenous characteristics of either sector. If either sector acts strategically—that is, based primarily on the anticipated response from the other sector—then the pairs themselves might be idiosyncratic. In other words, special patterns of regulatory behavior might characterize such pairs. One likely pattern is "splitting the territory"—the strategy by which both sectors adapt their behavior to avoid direct overlap. This problem is not unique to actual pairs, however. Strategic behavior is considered a primary characteristic of most private standards-setting. The nature and significance of the pair problem is examined in chapter 8.

The possibilities for "paired" case studies are limited mainly by the comparatively narrow scope of government regulation. There are private safety standards in almost every field where there are government standards. With so little known about these standards and the organizations that write them, however, it is difficult to know how potential case studies from the private sector fit into the larger universe of standards-setting.

Several considerations guided the choice of cases for this study. First, in order to permit an actual comparison of public and private decisionmaking, the cases had to overlap in content but have some degree of independence in development. In some cases, similar content denotes a lack of independent effort. Sometimes, a government standard is nothing more than a private standard with the force of law. The HUD mobile home standard was originally written by NFPA. The FDA relies largely on UL to evaluate microwave ovens. In other cases, the overlap is in title only. With many of the automotive safety standards, for example, the private sector (the Society of Automotive Engineers) writes test methods in areas where government standards specify performance levels.

These considerations narrowed the apparent field of possible pairs considerably, leading to the second consideration: how "representative" the pairs would be of the public and private sector. Recognizing that it would be impossible to select truly representative pairs without knowing more about the universe, particularly on the private side, selection was based on reputation. A primary goal was to examine private organizations with the best possible reputations, a variation on deviantcase analysis. Examining "best case" examples should provide a basis for estimating the outer bounds of the private sector's potential. Conversely, it should avoid the criticism that the sample is tilted toward the "bad apples."

By this reasoning, the most suspect class of private standards-setting organizations—trade associations—was eliminated from further consideration. Trade associations seem least likely to advance public purposes because of the narrow scope of their interests. Although trade associations vary more than is often appreciated, few have sufficient independence from immediate membership demands to seek a more enlightened, long-term course.[14] The remaining organizations—professional societies, general membership organizations, and third-party certifiers—are not necessarily better, but their form of organization suggests greater potential for something beyond parochialism.

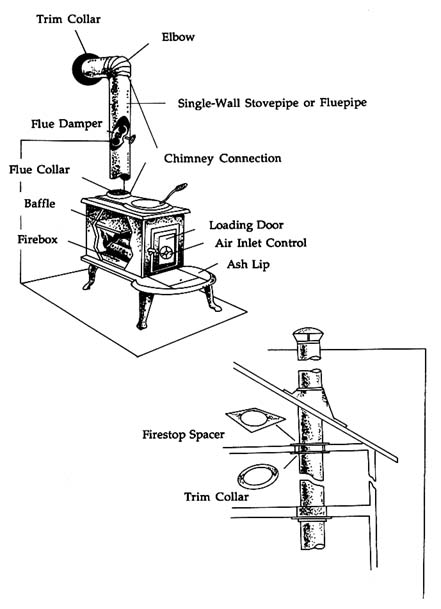

Within this grouping, UL clearly had to be one of the private organizations studied. It is not only the oldest and best-established private standards-setter; according to knowledgeable observers, it is also widely thought to be more independent and public-spirited than other private organizations. In addition, UL is most active in consumer products, an area in which standards policy may be most significant. Not coincidentally, there is practically no overlap between UL's standards and the few that have been successfully promulgated by the Consumer Product Safety Commission. UL actively seeks to keep the CPSC off its turf. The CPSC has considered getting involved in many areas regulated by UL, but the only case of dual standards is that of woodstoves. Accordingly, that is the first pair in this study.

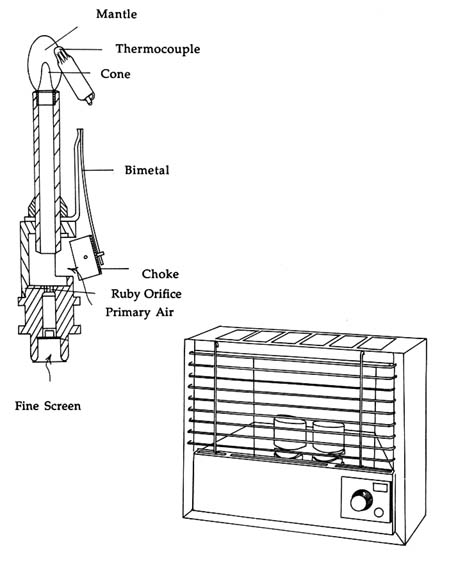

The overlap between UL and the CPSC is minimal in the woodstove case. Instead of developing a product standard for woodstoves, the CPSC supplemented UL's product standard with a labeling standard—an unusual form of CPSC regulation. Therefore, although the woodstove case offers an opportunity to examine UL, it appears to provide a peculiar view of the CPSC. Selection of the second pair was motivated by a desire to balance the woodstove case with one in which the CPSC adopted a full-fledged product standard—its more usual role in regulation. Given the CPSC's relative inaction in recent years, there were only two possibilities: lawn mowers and gas space heaters. The private sector's lawn mower standard was adopted by an ANSI committee under the sponsorship of the Outdoor Power Equipment Institute; the gas space heater standard was also adopted by an ANSI committee, but under the supervision of the American Gas Association Laboratories. The latter was chosen for two reasons. First, the gas space heater case is more recent, minimizing the chance that subsequent changes in either the public or private sector would render the findings outdated. Second, the lawn mower case has been studied many times; gas space heaters have not."[15]

Desire for a "best case" example of public standards-setting motivated the selection of the remaining cases. The CPSC may provide close to the "worst case" example of government regulation. The agency's short history has been marked by failure and poor judgment."[16] (An American Enterprise Institute study in 1983 suggested abolishing the CpSC.)[17] In order to ensure that the pairs were more representative of the potential for government regulation, the remaining cases had to involve government agencies with better reputations.

The possibilities included automobile safety (where there is some

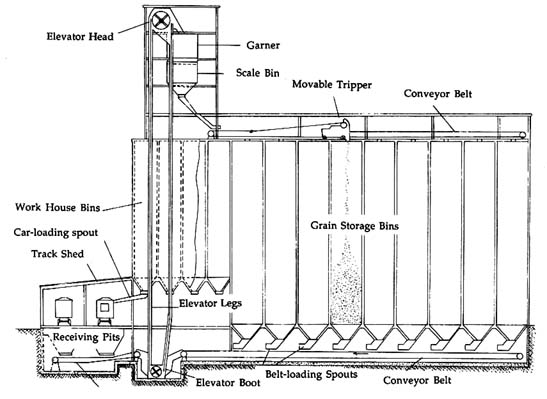

overlap between NHTSA and the Society of Automotive Engineers), nuclear power safety, aviation safety, and grain elevator safety. The first two were eliminated for practical reasons—they appeared to require a researcher to have substantial engineering (and possibly physics) background. Accordingly, the remaining cases were selected as the third and fourth pairs. In aviation safety, the FAA's 1984 proposal concerning fire extinguishers and smoke detectors overlaps directly with an NFPA standard. Although the FAA is criticized occasionally for an inadequate inspection and maintenance program, the agency enjoys strong congressional support and a surprising level of industry support for its regulatory activities.

The grain elevator case involves an OSHA standard, also paired with an NFPA one. Although OSHA's reputation, unlike the FAA's, is only a little better than the CPSC'S, this case study seemed appropriate for three reasons. First, it looked at "the new OSHA"—that is, OSHA under President Reagan. The grain elevator standard is one of only a few OSHA standards promulgated under the Reagan administration, and as such it might not be prone to the perceived excesses of previous OSHA standards. Second, like the CPSC, OSHA addresses the kinds of issues in which questions about the relationship between public and private standards are most likely to arise. Finally, the grain elevator case offered a research opportunity unavailable on the private side of the other selected cases: to observe the revision process in action. The NFPA grain elevator standard was due to be revised at a two-day subcommittee meeting in July 1985, offering an opportunity to observe the committee responding to comments and deliberating over specific language. This seemed likely to make possible a more complete and realistic view of private standards-setting than the other case studies (based as they are on documents and after-the-fact interviews).

Notes on Fieldwork